If your project calls for metal finishes with Declare documentation, you’ve found the right resource.

Add your feed to SetSticker.com! Promote your sites and attract more customers. It costs only 100 EUROS per YEAR.

Pleasant surprises on every page! Discover new articles, displayed randomly throughout the site. Interesting content, always a click away

Linetec

High-performance architectural finishes & coatingsLooking for Declare labels? Linetec anodized aluminum tops the list 18 Mar 2025, 2:20 pm

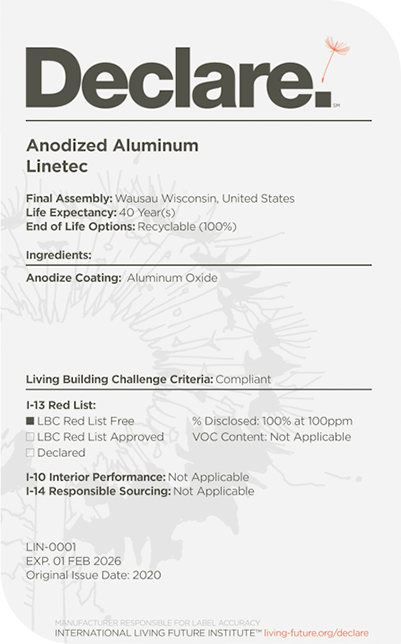

Linetec’s eco-friendly anodized aluminum has the only Declare label listed for shop-applied coatings for metal (Section 05 0513) including framing on windows, doors, curtain wall, storefront, as well as sun shades, wall panels and other architectural building products.

Architectural design, specification and building team members trust Declare labels when evaluating their architectural products and components. Declare labels offer material transparency and documentation for projects focused on sustainable construction and healthy spaces.

Declare labels may assist projects seeking certification through:

- S. Green Building Council’s LEED® Rating System

- International WELL Building Standard

- S. Environmental Protection Agency (EPA)’s Recommendations of Specifications, Standards, and Ecolabels for Federal Purchasers

- International Living Future Institute (ILFI)’s Living Building Challenge

(LBC) and Core Green Building Certification

(LBC) and Core Green Building Certification

Declare Defined

Building products with Declare labels are similar to a food with nutrition labels because they offer an easy-to-read summary of product material “ingredients.” These ingredients are voluntarily disclosed by manufacturers and screened against the ILFI LBC Red List.

All of Linetec’s anodized finishes, including Copper Anodize and Bordeaux Anodize, have earned a Declare label as LBC Red List Free. This means it is in full compliance with the highest level of LBC criteria.

To achieve LBC Red List Free, the manufacturer must disclose 100% of its product’s ingredients plus residuals present at or above 100 ppm in the final product, and the product cannot contain any LBC Red List items. Updated annually, this list catalogs chemicals and compounds with known risks to human health and the greater ecosystem.

Participating manufacturers also must renew their Declare labels every 12 months by resubmitting their disclosed ingredients. These requirements include ingredient disclosure thresholds, volatile organic compound (VOC) content and emissions, embodied carbon, and responsible sourcing.

The Declare label for our anodized aluminum further indicates that there are no applicable VOCs associated with this product. Anodize contains no VOCs and is inert, non-combustible and poses no health risks.

Long Life, High Value

The Declare label for Linetec’s anodized aluminum lists a life expectancy of 40 years. Beyond on its long life on the building, anodized aluminum is 100% locally recyclable. Choosing aluminum also supports environmentally responsible circularity as the metal can be reused without diminishing its material properties and versatility for upcycled products.

Because it is an integral part of the substrate, anodization produces an oxide film that is uniform, extremely hard and protects the rest of the aluminum from deterioration. After installation, the anodized aluminum’s longevity helps reduce the need for repairing or replacing the finished metal. These durable finishes also require minimal maintenance, saving time and costs, and adding value to the property and its owner.

Specify for Sustainability

Assisting architectural design and specification professionals, ILFI published The Living Building Challenge Specification Guidebook. Available free for download, it aligns with Division and section numbers included in MasterFormat®, developed by the Construction Specifications Institute (CSI).

Linetec provides additional guide specifications for architectural anodize and other shop-applied metal finishes (Section 05 0513) and their sustainable, high-performance attributes.

Our anodize finishes meet AAMA 611 Class I industry specification standards, providing excellent resistance to abrasion, weather, UV exposure and salt spray, and exceptional wear in high-traffic environments.

We subject our finishes to exterior exposure under extreme climate conditions on a test fence in south Florida. Copper Anodize, one of our proprietary color offering, has been on the test fence for 20 years with no significant change to color or gloss.

From copper to clear to champagne and bronze to black, the metallic tones of our eco-friendly anodize highlight the natural beauty of aluminum.

Single Source Solution

Whether your next project requires sustainable finishes, specialty coatings or other services, we’re here to help. Please contact your Linetec architectural sales representative for personalized assistance.

The post Looking for Declare labels? Linetec anodized aluminum tops the list appeared first on Linetec.

Dressed for stylish luxury in Copper Anodize cladding, the dual-branded Moxy “Lou” and Hotel Distil present a spirited, historically rooted, upscale Southern hospitality destination on Whiskey Row 6 Mar 2025, 4:03 pm

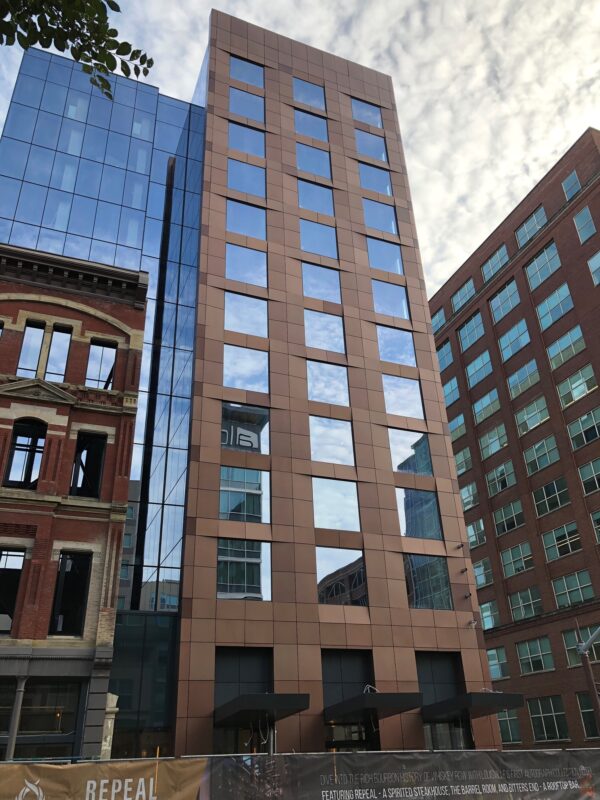

The 110-room Moxy “Lou” Louisville Downtown and the 205-room Hotel Distil -an Autograph Collection Hotel offer two distinct luxurious leisure experiences within a single, shared building on Whiskey Row in downtown Louisville, Kentucky. Respecting the area’s architectural legacy and historic address, the hotel tower features an aluminum cladding system by Crown Corr finished in a Copper Anodize by Linetec.

Located at 101 W. Main Street, the block used to be lined with bourbon and tobacco warehouses during the pre-Prohibition era. Today, the hotels’ design elements celebrate the area’s heritage with aged-barrels wood tones, blown-glass lights and flask art pieces, cask-inspired black metal accents and copper fixtures on the interior, and brick and Copper Anodized cladding on the exterior.

Two brands, one copper-colored tower

“Whether creating a dramatic new design, or conveying a historic depth and heritage, the classic beauty of Linetec’s Copper Anodize brings a rich, distinguished look to architectural building projects,” said Tammy Schroeder, marketing director for Apogee Enterprises’ Architectural Framing Systems segment and its Linetec brand.

The main entrance’s exterior retains the original façade of an 1860’s distillery’s barrel house and office that were saved from a 2015 fire. A newly constructed 14-story tower rises above this historic streetscape offering views of downtown and the Ohio River. The tower elevation facing Main Street showcases the Copper Anodized cladding.

Exclusive finish, lasting luster

“Thanks to Linetec’s proprietary process, the aluminum panels’ finish will maintain its elegant, rich copper color for years, possibly decades, to come,” said Schroeder. “With our exclusive copper-colored anodize for aluminum, you can achieve the look of real copper and lasting luster that doesn’t patina.“

Linetec’s proprietary and warrantied finish is accomplished through a three-step electrolytic coloring method, rather than the standard two-step process. The resulting finish remains a bright copper color, with no patina over time. It does not require a clear coat or ongoing treatment to maintain color stability. It is available for extrusion, stretch-formed and flat sheet aluminum, before or after assembly.

Further contributing to the hotel’s long life cycle, anodize aluminum resists the ravages of time, temperature, corrosion, humidity and warping, meeting the industry-leading AAMA 611 Class I specification. Protecting and maintaining the structural integrity of the aluminum, it retains exceptional hardness and lasting durability. Anodized aluminum is an inert, non-combustible material that is 100% recyclable and poses no health risks.

Versatile look, sustainable benefits

“Linetec’s Copper Anodized offers an environmentally responsible and economically feasible option to create dramatic new designs that shine, as well as to convey historic depth and rich heritage,” she added. “The finished aluminum is readily available, easily formed, extremely durable and can be recycled at the end of its long life on the building.” Anodized aluminum with a copper color finish also weighs less than half of real copper, for easier transportation and installation.

Recognizing these sustainable attributes, Linetec’s anodize finishing for aluminum has earned a Declare Label as Living Building Challenge (LBC) Red List Free. This means that Linetec’s anodize finishing, including Copper Anodize, is in full compliance with the highest level of LBC criteria established through the International Living Future Institute. The Declare Label for Linetec’s anodized aluminum indicates that there are no applicable VOCs (or any other harmful chemicals) associated with this product and lists a life expectancy of 40 years.

(LBC) Red List Free. This means that Linetec’s anodize finishing, including Copper Anodize, is in full compliance with the highest level of LBC criteria established through the International Living Future Institute. The Declare Label for Linetec’s anodized aluminum indicates that there are no applicable VOCs (or any other harmful chemicals) associated with this product and lists a life expectancy of 40 years.

Moxy Louisville Downtown and Hotel Distil-an Autograph Collection Hotel

- Exterior aluminum cladding – manufacturer: Crown Corr

- Exterior aluminum cladding – finishing services provider: Linetec

- Photos provided by: Crown Corr

The post Dressed for stylish luxury in Copper Anodize cladding, the dual-branded Moxy “Lou” and Hotel Distil present a spirited, historically rooted, upscale Southern hospitality destination on Whiskey Row appeared first on Linetec.

Belmont University campus features 10+ buildings with Linetec finishes on Tubelite storefront, curtainwall and entrances 25 Nov 2024, 6:11 pm

Across Belmont University’s Tennessee campus, curtainwall, storefront and entrance systems finished by Linetec help convey a campus-wide aesthetic that complements the functionality and personality of each space.

Through a decades-long partnership, glazing contractor Alexander Metals has installed Tubelite finished aluminum products on more than 10 buildings since 2011. These projects range from academic facilities to athletic centers and from performing arts spaces to student residences on a 93-acre setting located just two miles from downtown Nashville.

The Fisher Center for Performing Arts

Ensuring every project’s architectural vision, performance and sustainability requirements are upheld, Tubelite relies on Linetec as its single-source solution for its architectural finishing and value-added services. Linetec provides durable painted and anodized architectural finishing, high-performance thermal improvement and stretch forming to curve Tubelite’s aluminum fenestration and framing systems.

For Belmont University, Tubelite also worked closely with Alexander Metals, the University, the owner’s representative ChaseCo, and the team of architects and contractors. Many of the campus’ new and renovated structures featuring Tubelite aluminum framing systems were designed by architectural firm Earl Swensson Associates (ESa) and constructed by R.C. Mathews Contractor.

“It is an absolutely beautiful campus and with a lot of Tubelite framing systems,” said Tim Fookes, during a recent tour of the campus with Alexander Metals and Tubelite representative Gary Bowie of G. Bowie & Associates. Fookes serves as vice president of product engineering for Apogee Enterprises’ Architectural Framing Systems segment and Tubelite products.

Thousands of Belmont University’s students, faculty, staff and visitors have passed through Tubelite doors and gazed at the views framed by its curtainwall and storefront systems. Linetec’s durable finishing provides exceptional durability and performance, ideal for the heavy traffic and continuous use required by educational facilities.

For Tubelite and Linetec, must-stops on a visit to Belmont University include:

Thomas F. Frist, Jr. College of Medicine

Jack C. Massey Center

The Fisher Center for Performing Arts

The Curb Event Center’s Vince Gill Room

Crocket Center for Athletic Excellence, tennis facility and south parking garage

Gordan E. Inman Center, College of Health Sciences and Nursing

Caldwell Hall

Tall Hall

Thomas F. Frist, Jr. College of Medicine

Opened in May 2024, the new Thomas F. Frist, Jr. College of Medicine’s six-story, 198,000-square-foot facility features Tubelite 400 Series Curtainwall and custom wide stile doors finished by Linetec. Students have a choice of entrances when arriving at the College of Medicine. They can pass through Tubelite doors either on Wedgewood Avenue’s first floor entrance or on Acklen Avenue’s second floor entrance. Beyond the entrance and the lobby, the lower levels contain two-tiered learning theaters, a café and smaller classroom spaces.

The third and fourth levels have a Center for Interprofessional Engagement and Simulation, which offers immersive learning with advanced labs and fully simulated settings with patient volunteers. An anatomy suite for hands-on learning is on the fifth floor, as well as a library and terrace. Offices are located on the top floors and are organized in 10 Harry Potter-themed “houses,” which are increasingly adopted by medical school students.

Named in honor of Dr. Thomas F. Frist, Jr, co-founder of HCA Healthcare, the building is near existing nursing, pharmacy and health science buildings. According to ESa architects, the new facility extends the campus health and wellness corridor, offering an interprofessional educational experience for the fast-growing university.

Supporting the well-being of its students, staff and surroundings, all of Belmont University’s new construction are designed and built to meet LEED® certification sustainability standards. Geothermal systems’ renewable energy sources are used for efficient heating and cooling. The campus is designated as an Arboretum and USA Tree Campus combining water-conscious irrigation with ecologically diverse greenspaces.

Jack C. Massey Center

Opened in August 2023, ESa designed the Jack C. Massey Center’s six-story, 138,000-square-foot building to serve as Belmont University’s new, dedicated campus welcome and admissions center for prospective students and visitors. Named in honor of business leader Jack C. Massey, it also is home to the Belmont Data Collaborative, the Transformational Innovation Hub and the Cone Center for Entrepreneurship, and includes offices, computer science classrooms, Bruin Bites café and a campus spirit store.

“Situated on top of an existing, subterranean parking garage, the facility reflects the established campus context and completes the main campus quad, while its verticality creates a new monumental viewing point of the surrounding campus,” described ESa.

Framing these views, Alexander Metals installed Tubelite 400 Series Curtainwall system in 6- and 7.5-inch depths, and wide stile entrances. Promoting transparency and connection in the building’s indoor public spaces and large, inviting lobby, Tubelite INT45 interior framing systems also were installed. Along with outdoor views and interior daylight, the curtainwall’s high thermal performance supports the Center’s energy efficiency and comfort. These advantages can assist with its anticipated LEED v4 certification through the U.S. Green Building Council.

For the Massey Center, Linetec applied a 70% PVDF resin-based architectural coating in Bone White for Tubelite’s linear and curved framing systems. As an environmentally responsible finisher, Linetec uses a 100% air capture system and regenerative thermal oxidizer to safely destroy the VOCs in liquid paints’ solvents. By managing this in its quality-controlled facility, there is no adverse environmental impact at Linetec, on the jobsite or on campus. The finished aluminum curtainwall and entrance systems require only basic care and cleaning to maintain their intended appearance.

The Associated General Contractors (AGC) of Middle Tennessee recognized R.C. Mathews Contractor and the building team with 2024 Build TN Award of Excellence in the category for new institutional $75-80 million projects. The AGC award video noted:

“The Jack C. Massey Center is an incredible addition to the university’s growing campus, serving as the university’s new front door… Every floor of the six-story building includes incredible features and craftsmanship, and is designed to encourage collaboration, innovation and creativity. The project’s tight timeline and state-of-the-art technology advances demanded precise preplanning and coordination. Each space of the Jack C. Massey Center was carefully planned for a specific use, whether that be for collaborative spaces for students, ample offices for faculty, or wowing prospective students in the admissions theater. The Jack C. Massey Center will further enrich the on-campus experience and foster collaboration for students, faculty and visitors alike.”

The Fisher Center for Performing Arts

Opened in September 2021, the Fisher Center for the Performing Arts’ design by ESa showcases a composition of rectilinear and arched-top Tubelite aluminum-framed products to communicate the desired classical architectural style depicted on many of Belmont University’s significant structures. Alexander Metals installed Tubelite T14000 Series Storefront and 400 Series Curtainwall 8-inch-deep systems, plus 4.5-inch-deep 200 Series Curtainwall and wide stile doors.

The storefront and curtainwall were customized to meet the Fisher Center’s acoustic requirements. Tubelite’s high-performance systems also contributed to the project’s interior comfort and the building envelope’s energy efficiency – attributes in achieving the building’s LEED certification.

“This project is the biggest deal that I’ve ever been involved on,” said David Minnigan, AIA, IIDA, LEED AP, who was a principal at ESa before joining in 2023 Belmont University as its architect in residence. He called Fisher Center “a crowning jewel” of the campus and “something only a university with vision, like Belmont University has, can do.”

Named for former Belmont University president, Bob Fisher, the 155,000-square-foot Center hosts a 1,700-seat main auditorium, two contiguous recital halls, a grand lobby, and back-of-house areas including dressing rooms and rehearsal space. The entire interior space can be combined into a 900-seat banquet hall for special events.

From the outside, the building’s distinguished façade and expansive openings offer students and visitors a peek inside. The European-inspired grand lobby and recital halls display blue walls, hard wood and stone floors, and domed high ceilings. During the day, the interiors are illuminated with natural light thanks to Tubelite’s systems.

The Fisher Center’s architectural aluminum framing systems are finished to match the defining blue color and natural material palette. Tubelite’s 4.5-inch curtainwall and wide stile doors were custom-finished by Linetec using a durable mica coating in a Driftwood color. Linetec also provided Tubelite systems’ thermal improvement and stretch forming.

The project’s design and construction earned numerous accolades, including being selected as an Engineer News Record (ENR) national 2022 Best of the Best Projects of the Year award in the higher education/research category, an ENR Southeast’s 2022 Best Project in the higher education/research category and an ENR Southeast 2022 Project of the Year Finalist.

According to ENR Southeast: “Belmont University set out to create the finest performing arts center on any college campus, specifically designed to host a wide variety of events from theatre and opera to acoustic and amplified performances. …It was completed in four years and five days, a feat achieved with construction and design teams working hand-in-hand to mesh constructability with aesthetics. That includes combining Building Information Modeling (BIM) to work through complex coordination issues.”

In ENR’s award overview, one judge also commented, “It’s just so well executed, it’s unbelievable.” R.C. Mathews Contractor’s project manager, Scott Morgan, also is quoted as saying, “You could almost call it a once-in-a-lifetime project, it’s so unique. It’s almost like a musical instrument.” He also credited the long relationship with the University and ESa, and collaborative project team, adding, “They all work together so well, creating an atmosphere where if there’s a problem, everyone is comfortable with each other and can put their heads together for a resolution. …That really is what makes a project like that so fun to be on. You’re motivated to come work on it, and everybody wanting to go above and beyond, putting in 110%.”

Along with the prestigious ENR award, the project also earned a 2023 Traditional Building’s Palladio Award for new design and construction in the more than 30,000-square-foot category, a 2022 American School & University special citation, and an Associated Building and Contractors (ABC) national 2022 Pyramid Award and an ABC Greater Tennessee 2022 Excellence in Construction Award in the mega-project $100-160 million category.

The Curb Event Center’s Vince Gill Room

Opened in 2023,the Vince Gill Room features a roof plaza, box seats and Tubelite window wall and entrance systems. It is nestled within the new Curb Event Center’s entertainment and athletic complex.

Offering daylight, comfort and style, Alexander Metals installed Tubelite 900RW Series Therml=Block® Ribbon Window and wide stile doors in the Vince Gill Room. The 4.5-inch, thermally broken, aluminum-framed window wall delivers energy-efficient and condensation-resistant performance using multiple thermal barriers, while providing structural integrity and aesthetic flexibility. Enhancing the unified look with lasting durability, Linetec finished Tubelite framing systems using a 70% PVDF resin-based architectural coating in a custom Pebble color.

Tubelite’s products and Linetec’s finishing meet the Fenestration and Glazing Industry Alliance’s AAMA industry-leading performance standards. In addition, Tubelite Therml=Block systems are tested and modeled for thermal transmittance per the National Fenestration Rating Council’s procedures.

Along with the high performance of its building envelope, the Curb Event Center’s interior offers a 5,000-seat live performance space. It is connected to the student life center by way of the grand atrium to form a single structure. Opening the south side of the campus, the building follows the curving edge of the boulevard and complements adjacent community businesses.

Crocket Center for Athletic Excellence

Expanding on an already-planned parking garage topped with tennis courts, ESa designed the new Crocket Center for Athletic Excellence to encompass much more. The completed 45,820-square-foot structure offers a two-story lobby, a green roof, three basketball courts with electronic drop-down nets for volleyball, a conference room overlooking the court, coach and athlete support spaces, and separate lounges for basketball, volleyball and tennis, plus the parking garage. The innovative approach to the athletic facility earned a 2022 Learning by Design Outstanding Project Award.

Contributing to this award-winning project, Alexander Metals installed Tubelite wide stile entrance systems and center-set T14000 Series Storefront to create a welcoming and secure facility that transcends pure functionality. The natural light through the exterior openings is carried more deeply to the building’s core through Tubelite interior framing systems that allow for views onto the indoor court. In addition to the floor-to-ceiling interior openings, clerestory windows enrich the court’s daytime illumination.

Tubelite’s doors and framing systems were finished in Champagne Anodize by Linetec. This high-performance finish protects the metal and the light color enhances the natural beauty of the aluminum. Linetec maintains strict quality control procedures to ensure a very narrow range of color variation. Tubelite’s anodized aluminum framing systems also are recognized for their sustainable attributes, including earning a Declare Label as Living Building Challenge Red List Free. Anodize contains no VOCs and is an inert material that is not combustible and poses no health risks. The aluminum is 100% recyclable at the end of its long life on the building.

Red List Free. Anodize contains no VOCs and is an inert material that is not combustible and poses no health risks. The aluminum is 100% recyclable at the end of its long life on the building.

Gordan E. Inman Center, College of Health Sciences and Nursing

Unifying Belmont University’s health sciences and nursing programs, the new 215,000-square-foot Gordan E. Inman Center brings together related studies “from various makeshift back-of-the-campus locations to picture-postcard positioning at the front of the campus,” according to ESa. “In the university’s architectural vernacular, the structure looks as though it has always been in place as an integral component of the more than century-year-old campus.”

Defining the Inman Center’s exterior, Alexander Metals installed Tubelite Series 400 Curtainwall and storefront systems in a repeating pattern with varied dimensions. The main entrance showcases Tubelite wide stile doors with the openings above appearing narrower and taller than those at the top of the building. The corner tower’s window are wider in scale and crowned with octagonal portals above them, reflecting the decorative masonry. Linetec finished Tubelite’s aluminum framing in a Bone White 70% PVDF resin-based, high-performance architectural coating to blend with the surrounding stone.

Student Residential Halls

Alexander Metals also has installed a variety of Tubelite aluminum framing systems on numerous student residential buildings, including Dickens Hall (2012), Horrell Hall (2013), Russell Hall (2014), Tall Hall (2018) and Caldwell Hall (2022).

Caldwell Hall

Opened in 2022, Caldwell Hall’s 10-story, 268,000-square-foot residence tower is Belmont University’s largest residence hall. It comfortably houses more than 600 students within 162 units in 20 different configurations to meet the growing needs and preferences of its students. Tubelite 6-inch-deep Series 400 Curtainwall and medium stile entrance systems were selected by ESa to create a high-performance, collegiate Tudor-style exterior consistent contextually with the established campus architectural language.

Single, double and triple window bays feature precisely aligned and proportioned muntin grids to emphasize the Tudor detailing. All of Tubelite’s aluminum framing was installed by Alexander Metals and finished by Linetec in a Quaker Bronze color to further harmonize the appearance. Brick and light stone masonry provide contrasting visual layers within the physically articulated façade to separate the overall mass of the large structure.

University planners sought to accommodate growing enrollment by offering as many beds as possible with careful consideration for sustainability and adaptability. As part of its unique design, a three-story, atrium lobby overlooks the basement lounge at the elevated bridge entry. The interior framing system was created using Tubelite E4500 Series Storefront and was finished to match the exterior curtainwall.

The project and ESa were recognized with a 2023 outstanding design citation by American School & University.

Tall Hall

Positioned atop one of the highest elevations in Nashville, Tall Hall offers some of the city’s best views through Tubelite’s aluminum framing systems. At 243,000 square feet, the building also is Belmont University’s second-largest residence hall. In addition to its notable size, the building is certified LEED Gold.

Helping define this significant structure, Alexander Metals installed Tubelite 7.5-inch-deep Series 400 Curtainwall, center-set T14000 Series Storefront and medium stile doors. Tubelite’s high-performance aluminum framing systems also contribute to the building’s daylight and views, thermal comfort, energy efficiency and recyclable materials.

Supporting the classic academic styling Tubelite systems are finished by Linetec in Bone White to intentionally contrast with the traditional brick exterior. The uppermost window openings feature radius-topped curved framing accented with masonry arches. Horizontal framing were proportionally scaled across all openings – whether on a single room’s window bay or a multi-story three-sided stairwell tower enclosed with curtainwall.

As an environmentally responsible finishing services provider, Linetec paints and anodizes Tubelite aluminum framing using no- and low-VOC finishes, which were prioritized on Tall Hall. Linetec also serves as Tubelite’s single-source solution for stretch forming the curved aluminum and thermally broken framing, supporting the building’s aesthetic and performance goals.

Further demonstrating its commitment to sustainability, Belmont University reported 24% of all materials (by cost) installed on Tall Hall contain recycled content, energy use was reduced by at least 30% over a baseline building and approximately $107,950 in annual energy savings have been achieved. The project won ABC Greater Tennessee 2019 Excellence in Construction Merit Award in the $30-100 million category.

“It’s exciting to see what we’ve done here for our students,” said Belmont University’s president, Bob Fisher, at the project’s topping-out construction milestone. “The views from the top of this building, or even the views from the lower part of this building, are going to be spectacular. It’s going to house 611 of our students when it’s done.”

Fisher added, “This is our commitment to keeping our students close, keeping them as part of the Belmont community. We find that so many of our students want to stay on campus.”

Opened in 2018, Tall Hall provides more space for juniors and seniors to remain as residents on campus. As of 2024, there are 16 residential halls with more than 5,000 rooms available for students attending Belmont University.

Teamwork with Tubelite

Thanks to the collaborative approach between Tubelite, Linetec, Alexander Metals, R.C. Mathews Contractor, ESa architects, ChaseCo and Belmont University, a harmonious campus design continues to evolve and to support students’ academic growth.

Opened in 1890 with 90 students, Belmont currently serves an enrollment of approximately 10,000 students, the private university retains a 12 to one student to faculty ratio and offers more than 160 academic programs.

With respect to architectural legacy and consideration for setting and sustainability, Belmont University ranked #11 on Architectural Digest’s 2022 list of the prettiest college campuses in the United States that “create a place as beautiful as it is educational.”

Belmont University, 1900 Belmont Blvd., Nashville, TN 37212; https://www.belmont.edu

- Owner: Belmont University; Nashville, Tennessee

- Owner’s representative: ChaseCo; Nashville, Tennessee

- Architect: Earl Swensson Associates (ESa); Nashville, Tennessee; https://esarch.com

- General contractor: R.C. Mathews Contractor; Nashville, Tennessee; https://www.rcmathews.com

- Glazing contractor: Alexander Metals, Inc.; Nashville, Tennessee; https://www.alexandermetalsinc.com

- Architectural building products’ representative: G. Bowie & Associates; Nashville, Tennessee; http://www.gbowieandassoc.com

- Storefront, curtainwall and entrance aluminum framing systems – manufacturer: Tubelite; Wausau, Wisconsin; https://tubeliteusa.com

- Aluminum framing systems – finishing service provider: Linetec; Wausau, Wisconsin

- Photography: Sam Simpkins courtesy of Belmont University

- Virtual tour: https://www.belmont.edu/about/visit/virtual-tour.html

The post Belmont University campus features 10+ buildings with Linetec finishes on Tubelite storefront, curtainwall and entrances appeared first on Linetec.

Higher education facilities benefit from high-performance, finished architectural aluminum products 14 Aug 2024, 1:40 pm

Facility managers at universities, colleges, specialty training centers and other higher education institutions are faced with multiple challenges to balance fast-track construction schedules with enduring value. High-performance, finished architectural aluminum products help meet these needs and contribute to attractive, efficient and easy-to-maintain buildings.

Competitive advantage

Students have more options than ever to pursue their learning goals. There are more than 20 million people enrolled in 11,800+ post-secondary educational institutions in the U.S. While online education offers a convenient opportunity, many students learn better with in-person instruction and live discussion.

The largest higher-ed organizations are campuses with hundreds of individual structures that compose entire towns. Others are small, specialized programs contained within single buildings. In total, the U.S. dedicates approximately 5 billion square feet of floorspace to colleges, universities and other post-secondary facilities.

In addition to differentiation through academic programs, an educational institution’s beautiful, well-maintained facilities can offer a competitive advantage when recruiting and retaining both students and faculty.

Colorfully finished exterior wall cladding, entrances and window systems present a warm welcome for a diverse student population. Anodized finishes, and mica and metallic coatings emphasize an eye-catching, high-tech, modern look. Architectural paints and coatings can be selected in bright hues or customized to a school’s unique color palette. Linetec’s in-house blending lab can match colors for continuity or contrast across a campus, for historic renovations, for multi-phased expansions or to blend with the natural setting.

For the University of Massachusetts (UMass) Amherst’s John W. Olver Design Building, Linetec’s Copper Anodize finishes showcase a luxurious, rich, metallic appearance on Dri-Design’s aluminum panel rainscreen system. Leers Weinzapfel Associates (LWA) selected the colors and materials for their distinguished appearance, their integration with the architectural palette of the campus, and their biophilic connection with the timber and metal of the area’s natural, rural environment.

The UMass project’s environmental and sustainable attributes earned the Design Building LEED® Gold certification through the U.S. Green Building Council and numerous awards. Among its honors, the building was recognized by the American Institute of Architects (AIA) Committee on the Environment with a Top Ten Award and by AIA New England with a Merit Award for Design Excellence.

Photo courtesy of Dri-Design

Photo by Integrated Design Solutions, Kevin S. Marshall, courtesy of The Sherwin-Williams Company (Valspar)

The Bio Engineering Facility at Michigan State University (MSU) features a palette of gray, white and black to distinguish the new facility from both the traditional red brick of the campus standard and beige of the cast concrete of the more recent structures. To ensure a consistent appearance and uniform white color across the exterior aluminum building products, Integrated Design Solutions (IDS) relied on Linetec to finish Tubelite’s curtainwall and entrance systems in high-performance architectural coatings. Utilizing the latest technologies to analyze and formulate thousands of color variations ensures creation of the exact color specified.

Lessons in energy savings

According to the U.S. Department of Energy (DOE), post-secondary institutions are spending more than $6 billion on energy costs each year. Facility managers typically focus first on lighting and HVAC upgrades to incrementally increase energy savings. Significant savings can be gained by improving building envelope thermal performance with high-performance curtainwall, storefront, entrance, window and other fenestration systems.

Fenestration product manufacturers also save time and headaches when they partner with a single-source solution for architectural finishing and energy improvement. At Linetec, we conveniently coordinate everything in one location. We offer a choice of poured-and-debridged or polyamide insulating strips to improve aluminum-framed products’ thermal performance. We provide thermal improvement services for arched and circular shaped framing, and offer stretch forming to bend and curve your aluminum extrusions prior to finishing. Our finished flat sheet also is stocked and available for quick shipping.

In addition to improving fenestration products’ thermal performance, low- and no-VOC finishes may assist higher education projects in meeting LEED criteria and sustainability goals. Anodized finishes contain no VOCs. Linetec’s anodize process by-products are recyclable and anodized aluminum is 100% recyclable. To safely remove the VOCs in the liquid paints’ solvents, Linetec uses a 100% air capture system and regenerative thermal oxidizer. By managing this in its quality-controlled facility, there is no adverse environmental impact either at Linetec or on the jobsite.

As the new home of the Washington University’s (WashU’s) Department of Computer Science & Engineering, James M. McKelvey, Sr. McKelvey Hall was designed to be 30% more efficient than a standard building and is certified LEED v4 Gold. Perkins Eastman and the project team followed an integrated design process incorporating the principles of sustainable design with attention to energy efficiency, low-impact materials, reuse and recycling, quality and durability, and health and wellness.

As a single-source solution, Linetec provided both the high-performance finishing and thermal improvement services for the aluminum-framed fenestration products from Tubelite and Wausau Window and Wall Systems. The window wall, curtainwall, entrance and shading systems were finished in “Amazing Gray” and “Noble Gray” colors.

Linetec applied the high-performance 70% PVDF resin-based architectural coatings, including safely capturing and destroying the solvent VOCs before the finished materials exited the paint line. Every material selected for McKelvey Hall was screened against a multitude of variables, including LEED v4 requirements, Red List chemicals, healthcare-level standards outlined in the Healthier Hospitals Initiative and the WELL Building Standard .

.

Photos by Paúl Rivera

Valuable investment

Post-secondary institutions seek to instill a sense of credibility and permanence through their facilities. To see an aging structure in disrepair subconsciously erodes our trust in the value of the education offered within its walls.

High-performance finished aluminum products support a lasting, positive impression. Anodized finishes provide exceptional durability to withstand daily use. To ensure the highest level of performance, specify AAMA 611 for Class I anodize coatings.

Photo by Charles LeRette Photography, courtesy of Tubelite

Designed by PQH Group, Florida’s Embry-Riddle Aeronautical University’s 650-bed student residence hall incorporates an ultra-modern look, natural light, campus views, and comfortable living and learning environment. To meet the project’s required aesthetic, sustainability and performance specifications, Tubelite manufactured the window, curtainwall, storefront and entrance systems, and an airfoil fin.

In compliance with AAMA 611 specifications, Linetec anodized all Tubelite systems to enhance the building’s high-tech aesthetic and to provide high-performance protection from Florida’s extreme coastal conditions and the students’ daily use. The anodized aluminum resists the ravages of time, temperature, corrosion, humidity and warping, with minimal maintenance.

For painted finishes, specify AAMA 2605 for 70% PVDF resin-based coatings. These top-class finishes require very little maintenance and are easy to clean, which minimizes the associated costs for labor, repairs and replacement.

The Elmer Buchta Technology Center supports the immediate and future educational and employment needs of Pike County, Indiana. The cheerful multi-colored building creates a welcoming presence in the community. Designed by Hafer, the exterior features a metal rainscreen wall panel system manufactured by John W. McDougall Company Inc.

To maintain its inviting appearance, Linetec finished the 629 panels using 70% PVDF-resin based architectural coating systems in four different colors: Bone White, Cityscape Gray, a dark Regal Blue and a light Siam Blue.

Linetec applied the finishes under quality-controlled conditions to meet the industry’s most stringent performance specification, AAMA 2605. Protecting and enhancing the aluminum panels, these coatings’ strengths include resistance to color change, gloss loss, chemicals, UV, chalking, erosion, humidity and salt spray.

Photos by Richard Chisum, Chisum Multimedia; courtesy of John W. McDougall Company, Inc.

High-quality, high-performance, finished architectural aluminum products enrich the institutional investment in higher education facilities and their long-lasting, energy-efficient, cost-effective operation.

The post Higher education facilities benefit from high-performance, finished architectural aluminum products appeared first on Linetec.

Protecting our public investments: High-performance finishes add value to governmental and civic facilities 7 Aug 2024, 2:15 pm

Serving the needs of the public, our governmental and civic spaces must be built to balance long-term operational efficiency, resiliency, functionality and affordability with respect to taxpayer dollars. High-performance, finished architectural aluminum building products maximize our collective investment in public properties, helping deliver life-long value for current and future generations.

Choosing high-performance finishes protects aluminum architectural products’ durability and longevity. This in turn minimizes government buildings’ maintenance while saving labor, repairs, replacement materials and related costs. Selecting a partner who offers both architectural finishing and energy improvement services gives window and door manufacturers an advantage in meeting the needs of our federal, state, local and municipal buildings.

Reduce Maintenance, Increase Savings

The U.S. Government Accountability Office (GOA) recently reported that the cost of deferred property maintenance and repair increased approximately $22 billion between 2017 and 2022 for four selected federal agencies. Among the agencies reviewed, the General Services Administration (GSA) showed an increase of 126%.

The GSA owns and leases more than 363 million square feet of space in 8,397 buildings in more than 2,200 communities nationwide. The GSA’s 2024 Federal Buildings Fund specifically noted the need to address “façades and inefficient deteriorating window systems” as a “critical work item.”

Minimizing maintenance and repairs on our existing government properties and public buildings can save Americans billions of dollars. When upgrading, renovating and retrofitting these facilities, high-quality, high-performance, finished aluminum architectural products support low-maintenance, cost-effective operation.

Linetec provides aluminum product manufacturers with a choice of finishing solutions suitable for maintaining our civic institutions. To ensure the highest performance level, specify AAMA 2605 for 70% PVDF resin-based painted coatings and AAMA 611 for Class I anodized finishes. These AAMA specification standards are published by the Fenestration & Glazing Industry Alliance (FGIA).

Because most government facilities serve a large number of people, the aluminum surfaces on both the high-traffic exteriors and interiors benefit from these exceptionally hard-wearing and long-lasting finishes. Building products with 70% PVDF resin-based painted coatings and Class I anodized finishes can remain in service for several decades.

Opened in 1898, the Adair County Courthouse in Kirksville, Missouri, is listed on the National Register of Historic Places. In recent years, maintenance of the building had been neglected due to a lack of sufficient funding. During its 120+ years of public service, the building’s windows had been replaced, but these also were now outdated, inefficient and in disrepair. With community support through a quarter-cent capital improvement sales tax, the county was able to make necessary performance upgrades, while preserving the historical appearance, including its radius and elliptical shapes.

Winco Windows worked with Linetec to maintain the existing window openings’ shapes and aesthetic. Linetec finished the aluminum replacement windows and trim using a high-performance Class I anodize in a Medium Bronze color. Finished-to-match aluminum panning was wrapped over the existing frames to improve the courthouse’s appearance and provide a low-maintenance solution.

The new, finished aluminum, thermally broken casement and single-hung units from Winco Window significantly increased the courthouse building’s energy and operational efficiency, and returned the property to its attractive, prominent position in the downtown area.

Lead by Example

With more than 300,000 buildings, the U.S. government is the single largest energy consumer and building manager in the nation. Improving these buildings’ energy efficiency and performance presents another critical opportunity to save operational costs, conserve resources and reduce emissions. Government findings indicate that buildings are a significant contributor to carbon emissions, with building operation comprising 28% of total annual greenhouse gas emissions, and building materials and construction comprising another 10%.

To improve our future outlook, the Federal Sustainability Plan established an ambitious path to achieve net-zero emissions by 2045. The federal government’s plan also includes midpoint goals for 2032 to achieve a 50% reduction in building emissions and a 65% reduction in building operations. Implementing the plan involves deep energy retrofits for existing facilities. All new construction and major modernization projects larger than 25,000 square feet must be net-zero emissions by 2030.

Committed to these goals, the GSA uses the U.S. Green Building Council’s LEED® green building certification system as a tool for evaluating and measuring achievements in sustainable design. The GSA requires, at a minimum, new construction and substantial renovation of federally owned facilities to be LEED Gold. Leased buildings are required to earn an ENERGY STAR® label.

The Lowell Justice Center is the first courthouse in Massachusetts to be LEED Platinum certified. Finegold Alexander Architects designed the seven-story, 265,000-square-foot building to demonstrate the state’s commitment to net-zero energy initiatives, environmental and economic responsibility.

Helping achieve its goals, Linetec finished Wausau Window and Wall Systems’ curtainwall, ribbon windows and punched openings using 70% PVDF resin-based architectural coatings in Flagstone and Knights Armor gray colors to complement the justice center’s granite cladding. In addition, Linetec painted Wausau’s zero sightline vents, terrace doors and factory-assembled sun shade systems in matching colors.

The window systems’ extruded aluminum framing was manufactured with a high recycled content in three different sizes. Linetec’s painted finishes help conceal small imperfections in the secondary billet. The aluminum framing system was engineered with 3/8-inch thermal separation and helps reduce the building’s energy by 40% compared to similar facilities.

Energy-Efficient, Environmentally Responsible

Manufacturers of high-performance, aluminum-framed window, curtainwall, storefront and entrance systems play a key role in contributing to government buildings’ ENERGY STAR labeling, LEED certification and sustainable requirements.

As a single-source solution, Linetec conveniently coordinates finishing and thermal improvement services for you in one location. We offer poured-and-debridged or polyamide insulating strips as thermal barriers in aluminum framing systems. Finished fenestration systems with high thermal performance can attain the net-zero energy requirements of federal buildings, as well as improve energy efficiency for other state, local and other public facilities.

In addition to energy efficiency, government and civic projects frequently request low- and no-VOC finishes to meet LEED criteria and sustainability goals. Anodized finishes contain no VOCs. Linetec’s anodize process by-products are recyclable and anodized aluminum is 100% recyclable. To safely remove the VOCs in the liquid paints’ solvents, Linetec uses a 100% air capture system and regenerative thermal oxidizer. By managing this in its quality-controlled facility, there is no adverse environmental impact either at Linetec or on the jobsite.

LEED and other governmental sustainable and design guidelines recognize the benefits of daylighting and views. For example, the U.S. Courts Design Guide highlights that “windows allowing an exterior view and natural light are highly desirable” in judges’ conference rooms, court libraries, offices and other areas.

Michigan’s family division of the Kalamazoo County Circuit Court is housed within the new, three-story Gull Road Justice Complex. The 85,000-square-foot government center also includes judges’ chambers, hearing rooms, courtrooms, holding rooms, and offices for the court clerk, Friend of Court and county prosecutor, and is linked to the Juvenile Detention Center via an enclosed walkway. Architects at TowerPinkster and HOK worked with the County to design a facility that conveyed a transparency and connection to the community, while providing a secure and functional structure.

Meeting the project’s aesthetic and performance goals, Tubelite fenestration systems were installed on both the interior and exterior, maximizing views and daylight. Linetec finished all Tubelite curtainwall, storefront, entrances, interior framing and exterior sun shades in a durable, easy to clean and maintain, no-VOC Class I clear anodize. Thermal improvement services also were provided to contribute to the occupants’ comfort and the building’s energy-efficient operations. During summer months, cooling costs can be significantly lowered with sun shades, while still allowing natural light to fill the interior The resilient anodized finish will protect the justice complex’s architectural aluminum products and preserve its appearance for many years to come.

Curves, Color and Customization

From historic national monuments and state capitols to modern county justice centers and local libraries, our government and civic buildings come in all sizes, styles and shapes. Their architecture typically presents a sense of institutional permanence with sturdy foundations and strong construction materials. Using finished aluminum-framed glazing systems combines the durable reliability with transparency and a visual connection between the interior space and the community.

Contemporary designs incorporate storefront, curtainwall, window wall and entrance systems with protective qualities that can enhance security and resist earthquakes, hurricanes and extreme temperatures.

Listed on the National Register of Historic Places, New Orleans’ Gretna City Hall has served its community as government building since 1907, weathering hurricanes and time. City leaders committed to upgrading the old, water-damaged windows with high-performance, hurricane impact-resistance units. In addition, the local historical review boards ensured that the replacement windows would replicate the original historic appearance including their sculpted trim.

To deliver the required performance and aesthetic, Winco Window partnered with Linetec to finish the new single-hung windows using a 70% PVDF resin-based architectural coating in a Bone White color to match the original windows’ ornate trim and panels. Winco’s windows feature an integral sloped exterior glazing leg with hurricane-resistance laminated glass and weather-tight construction. The high-performance finish meets AAMA 2605 specifications and helps protect the aluminum from New Orleans’ coastal salt spray and humidity.

One of the first net-zero energy fire stations in the country and LEED Gold-certified, Salt Lake City’s Fire Station No. 14 features high-performance, aluminum framing systems from Tubelite finished by Linetec in durable, clear, Class I anodize. Blalock & Partners Architectural Design Studio worked with fire station specialist TCA Architecture + Planning to meet all of the project’s objectives.

Salt Lake City’s net-zero energy facilities mandate and “Climate Positive 2040” plan seek to achieve net-100% renewable electricity by 2030 and to reduce carbon pollution by 80% by 2040. Exemplifying this directive, Station 14 features a solar panel roof array, geothermal heating and cooling, and high thermal performance building envelope. Creating the station’s high-performance façade, Tubelite provided its triple-glazed 400TU Series Therml=Block® curtainwall, as well as its T14000 I/O Series multi-pane storefront, operable windows, side entrance doors and INT45 interior framing systems.

Along with anodizing all the Tubelite systems, Linetec provided the dual, thermal polyamide insulating strut for its curtainwall. The high-performance systems and low-maintenance, durable finishes support the city’s long-term, energy-efficient and cost-effective goals.

Clear anodized finishes and mica and metallic coatings emphasize a high-tech, modern appearance. Classic architectural designs often feature arched and circular shaped framing. When updating to modern fenestration, Linetec can provide stretch forming to bend and curve your aluminum extrusions prior to finishing. Our in-house blending lab can match colors for aesthetic continuity between eras and expansions.

Architectural aluminum products also can be selected with specialty finishes that resemble other construction materials, often at a more economical price point and with all the benefits of finished aluminum.

- Want the warmth of wood without the maintenance? Check out our wood grain finishes for aluminum.

- Want the high-end appearance and tactile feel of terra cotta without the expense? Touch our textured terra cotta

- Want the shiny copper of a new penny without the patina? Take a look at our Copper Anodize.

- Want a marble wall panel without the heavy lifting? Talk to us about spattercoat.

An exterior color can quickly communicate the space’s purpose to the public. From firehouse red to postal blue to library bronze, Linetec has the finishes to match your project’s message. You also can find plenty of tan, beige, gray, black and silver shades in our Color Select and Spec online library of more than 60,000 color chips, as well as our full range of anodize color finishes.

For personalized assistance in finding a finish to fit your next government building project, please contact your Linetec sales representative.

The post Protecting our public investments: High-performance finishes add value to governmental and civic facilities appeared first on Linetec.

EFCO, Linetec and Tubelite marketing team members judge Glass Magazine Awards 30 Jul 2024, 6:32 pm

We are proud to have Glass Magazine Awards’ 2024 judging panel include three marketing team members with Apogee Architectural Framing Systems:

Sara Barchak

representing the EFCO and Wausau Window legacy brands

Austin Zajichek

representing the Linetec brand

Brian Tobias

representing the Tubelite brand

Drawing from their industry experience and marketing expertise, Sara, Austin and Brian independently evaluated numerous Glass Magazine Award entries in six categories recognizing the best architectural glass products and eight categories for the best projects.

Glass Magazine is the official publication of the National Glass Association (NGA) and the GlassBuild America expo. NGA members and readers also were eligible to vote online for the finalists. The August/September issue of Glass Magazine will highlight the judges and feature all the award winners.

During GlassBuild America, the 2024 Glass Magazine Award winners also will be honored at an event on Tues., Oct. 1, 3:45-4:15 p.m., on the Main Stage #199009. Everyone at GlassBuild America is welcome to join in applauding these exceptional products and projects. Attendance is free, but registration is required.

EFCO, Linetec and Tubelite representatives will be attending GlassBuild America, which takes place Sept. 30-Oct. 2 at the Kay Bailey Hutchison Convention Center in Dallas. Expo hours are 10 a.m.-5 p.m. on Monday and Tuesday, and 9 a.m.-1 p.m. on Wednesday.

For more on the awards and events, follow Glass Magazine, NGA and #GlassBuild America on social media at:

The post EFCO, Linetec and Tubelite marketing team members judge Glass Magazine Awards appeared first on Linetec.

Linetec’s finishes match color and performance for the National Aquarium’s iconic skylight renovation by Super Sky 24 Jul 2024, 3:06 pm

The National Aquarium in Baltimore renovated its iconic pyramid-shaped skylight that caps its “Upland Tropical Rain Forest” immersive exhibit on Pier 3 of the Inner Harbor. The project was completed in partnership with architectural firm Design Collective, general contractor Plano-Coudon and Super Sky Products Enterprises. According to the Aquarium, this critical improvement ensures the future of the glass pyramid for the next half-century.

To refresh its appearance and update its performance, Super Sky teamed with Skylight Partners of America to repair and replace the existing skylight. Where necessary, Super Sky manufactured and installed new aluminum framing systems. Along with bird-friendly glass, the updated skylight features aluminum framing finished by Linetec to meet coastal conditions and to preserve the existing exterior and interior color palette.

To refresh its appearance and update its performance, Super Sky teamed with Skylight Partners of America to repair and replace the existing skylight. Where necessary, Super Sky manufactured and installed new aluminum framing systems. Along with bird-friendly glass, the updated skylight features aluminum framing finished by Linetec to meet coastal conditions and to preserve the existing exterior and interior color palette.

Super Sky’s renovation manager, Todd Wilde, enthusiastically shared his compliments saying, “This very high-profile, monumental project turned out looking great and was a very successful project. There is great satisfaction in seeing your repair concept come to fruition, get completed without too many issues, look like a brand-new product once completed and know that you helped the owner improve the aesthetics and performance of the buildings – all while minimizing the impact to the occupants.”

Finding an ideal (color) match

For many years and many high-profile projects, Super Sky has relied on Linetec as its single solution for architectural finishing. To help ensure color consistency with the critical appearance, Linetec paint technicians examine a finished part from the existing building to create the closest match possible. Even if the precise details from the original finish are known, adjustments can be made so the newly finished material aligns with the correct vintage of color currently on the building.

For many years and many high-profile projects, Super Sky has relied on Linetec as its single solution for architectural finishing. To help ensure color consistency with the critical appearance, Linetec paint technicians examine a finished part from the existing building to create the closest match possible. Even if the precise details from the original finish are known, adjustments can be made so the newly finished material aligns with the correct vintage of color currently on the building.

“For existing buildings in need of color matching, our unparalleled expertise ensures near-perfect results,” said Tammy Schroeder, director of marketing for Linetec. “We use the latest technologies to analyze and formulate thousands of color variations, ensuring creation of the exact color specified. With our in-house experts and computerized blending capabilities, we’ve applied more than 65,000 unique colors.”

For Super Sky’s aluminum-framed skylight system on the National Aquarium, the design team specified Quaker Bronze as the color. Different paint coating manufacturers each have their own special shades of Quaker Bronze. To ensure the correct match, the design team references the unique Linetec color code, which is LT602. This is one of 20 standard in-house colors offered by Linetec. Standard colors generally provide the most economical choice for architectural coatings, while still delivering the highest performance painted finish.

Ensuring durable finishes for coastal environments

In addition to matching the aesthetic requirements for finishing Super Sky’s aluminum-framed skylight system on the National Aquarium, Linetec also meets the high-performance requirements for the project. The design team specified a 70% fluoropolymer resin-based coating that meets AAMA 2605. Published by the Fenestration and Glazing Industry Alliance (FGIA), this is the most stringent industry standard for painted coatings available for aluminum-framed skylights and other architectural aluminum building products.

In addition to matching the aesthetic requirements for finishing Super Sky’s aluminum-framed skylight system on the National Aquarium, Linetec also meets the high-performance requirements for the project. The design team specified a 70% fluoropolymer resin-based coating that meets AAMA 2605. Published by the Fenestration and Glazing Industry Alliance (FGIA), this is the most stringent industry standard for painted coatings available for aluminum-framed skylights and other architectural aluminum building products.

For the National Aquarium, Linetec applied a PPG Duranar® two-coat architectural liquid paint to Super Sky’s extruded aluminum framing members under factory quality-controlled conditions. Standard color two-coat systems consist of a primer and color coat. The Duranar coating’s fluoropolymer formulation includes 70% polyvinylidene fluoride (PVDF) resin.

Considering Baltimore’s hot summers, cold winters and proximity to the coast, fluoropolymer coatings with 70% PVDF resin offer the ultimate protection in building performance. In compliance with AAMA 2605, these finishes exhibit outstanding resistance to humidity, color change, chalking, gloss loss, chemicals and salt spray. Linetec ensures a long-lasting, durable finish, typically supported with a 10-year warranty. No other coating system can withstand the rigors of nature and time like those based on 70% PVDF resin coatings.

Respecting the environment – inside and out

As an environmentally responsible finisher, Linetec safely captures and destroys volatile organic compounds (VOCs) associated with liquid coatings during its paint application process and repurposes the heat produced from their reclamation. This means that when the finished products from Linetec are installed on a building project, such as the National Aquarium, there are no adverse effects from “off gassing” on the building’s indoor air quality or on its human and animal occupants.

As an environmentally responsible finisher, Linetec safely captures and destroys volatile organic compounds (VOCs) associated with liquid coatings during its paint application process and repurposes the heat produced from their reclamation. This means that when the finished products from Linetec are installed on a building project, such as the National Aquarium, there are no adverse effects from “off gassing” on the building’s indoor air quality or on its human and animal occupants.

The renovated skylight also helps protect the birds outside the National Aquarium. The glass panes had not been replaced since the National Aquarium opened 41 years ago and were due for an upgrade. Design Collective selected an opaque glass with an acid-etched pattern that deters bird collisions.

The new glass and the skylight’s surrounding LEDs minimize light pollution, creating an ambient nighttime glow from the outside. On the inside, the glass provides a diffused light and its low-e coating helps maintain the required climate, offering a comfortable experience for both animals and guests. Visitors can see a variety of colorful tropical birds, two-toed sloths, blue poison dart frogs, yellow-footed tortoises and golden lion tamarins, along with 160 species of continuously growing plants from South America that feed and shelter the animals.

Overcoming challenges for a successful completion

Replacement and installation on the Aquarium skylight’s 679 glazing units began in March 2022 and progressed as planned through completion in September. To replace the pyramid’s glazing, the team needed to work at 96-foot heights on a sloped surface.

Replacement and installation on the Aquarium skylight’s 679 glazing units began in March 2022 and progressed as planned through completion in September. To replace the pyramid’s glazing, the team needed to work at 96-foot heights on a sloped surface.

“There are not many subcontractors in the country qualified to do this kind of work,” said Plano-Coudon’s vice president, Cliff Milstead, LEED AP. “They did a really great job figuring out some challenging logistics.”

At the November 2022 reopening celebration event, National Aquarium’s president and CEO John Racanelli said, “Though many of the changes… may not be noticeable to the eye, they have greatly improved the environment for the animals and plants, as well as made it safer for our staff.”

Recognizing the thoughtful and successful renovation, the National Aquarium and its project team have received several accolades. At the Associated Builders and Contractors of Greater Baltimore’s 2023 Excellence in Construction Awards, the project was recognized as a Gold Winner. The Metropolitan Baltimore’s Building Congress & Exchange also honored the project with multiple 2023 Craftsmanship Awards including for the skylight renovation and for the overall building.

The National Aquarium; “Upland Tropical Rain Forest” exhibit, 501 E. Pratt St., Baltimore, MD 21202; https://aqua.org/explore/exhibits/upland-tropical-rain-forest

- Architect: Design Collective; Baltimore; https://www.designcollective.com

- General contractor: Plano-Coudon, LLC; Baltimore; https://plano-coudon.com

- Façade/glazing contractor and skylight manufacturer: Super Sky Products Enterprises, LLC.; Milwaukee; https://www.supersky.com

- Glass replacement contractor: Skylight Consultants of America, Inc.; Indianapolis

- Aluminum framing finishing service provider: Linetec, a brand of Apogee Enterprises, Inc.; Wausau, Wisconsin

- Photography: Prime Meridian Photo, courtesy Super Sky Products Enterprises

- Installation videos – Skylight Consultants of America: https://www.youtube.com/@nationalaquariumskylightre6958/videos

The post Linetec’s finishes match color and performance for the National Aquarium’s iconic skylight renovation by Super Sky appeared first on Linetec.

Hilton’s Southeastern hotel prototype showcases Linetec finishing and thermal improvement services on Tubelite window wall and entrances 24 Jul 2024, 1:32 pm

As the Middle Tennessee’s first full-service hotel built in nearly a decade, the eight-story, 244-room Hilton Franklin Cool Springs offers one of the only roof-level patios in town plus a stylish lobby and contemporary guest rooms with Tubelite thermal entrance systems and floor-to-ceiling window wall. Presenting a welcoming, business-friendly palette, Linetec finished all of Tubelite’s aluminum framing systems using a Light Seawolf Beige color and thermally improved the system for optimal performance in the hot, humid climate.

Designed by Rabun Architects, the 163,500-square-foot property is a prototype for Hilton’s Southeastern full-service facilities and one of the largest hotels in the fast-growing Williamson County. The building’s mass is defined and visually distributed with intention, contrasting solid precast concrete with transparent glazing.

Tubelite 900RW Series Thermal Window Wall balances vertical orientation with clean, horizontal lines on Hilton Franklin Cool Springs. Tubelite Thermal=Block® TerraPorte Doors are well-suited for main or side entrances, and balcony and terrace doors. Delivering a unified look with lasting durability, Linetec finished all Tubelite entrance and framing systems using a 70% PVDF resin-based architectural coating. This finish meets the Fenestration and Glazing Industry Alliance’s AAMA 2605 performance specification requirements, the most stringent industry standard.

Tubelite 900RW Series Thermal Window Wall balances vertical orientation with clean, horizontal lines on Hilton Franklin Cool Springs. Tubelite Thermal=Block® TerraPorte Doors are well-suited for main or side entrances, and balcony and terrace doors. Delivering a unified look with lasting durability, Linetec finished all Tubelite entrance and framing systems using a 70% PVDF resin-based architectural coating. This finish meets the Fenestration and Glazing Industry Alliance’s AAMA 2605 performance specification requirements, the most stringent industry standard.

Coatings that meet AAMA 2605 exhibit outstanding resistance to color fade and change, chalking, gloss loss, humidity, salt spray and chemicals. They also require minimal care and cleaning. These attributes are especially important for high-traffic hotels, where doors are in continuous use and maintaining a professional appearance contributes to both property and brand value.

As an environmentally responsible finishing provider, Linetec uses a 100% air capture system and regenerative thermal oxidizer to safely destroy the VOCs in liquid paints’ solvents. By managing this in its quality-controlled facility, there is no adverse environmental impact at Linetec, on the jobsite or in the hotel. The finished aluminum doors and window systems require only basic care and cleaning to maintain the hotel’s desired impression.

In addition to helping create a high-end, modern aesthetic for Hilton Franklin Cool Springs, Linetec and Tubelite also support a comfortable experience for business travelers in Tennessee’s warm weather. Linetec thermally improved Tubelite aluminum entrances and window wall framing members using poured-and-debridged ultra-thermal barriers. This thermal break separates and insulates the framing to reduce conduction, AAMA standards for air, water, structural and condensation resistance.

Tubelite 900RW Series Thermal Window Wall has been tested to deliver as low as 0.32 U-Factors for thermal performance. Tubelite Thermal=Block TerraPorte Doors also are verified for security, accessibility, egress and dependable operation with continuous use. Tubelite window wall and entrances are engineered for easy integration and installation, saving time, labor and associated costs.

For Hilton Franklin Cool Springs, glazing contractor McInerney and Associates worked closely with Crain Construction and Tubelite to stay in budget and on schedule. “Since the hotel was a prototype with unique finishes, the design team was constantly modifying. Subcontractors did modeling and close coordination with the design team to expedite the shop drawing review process and allow materials to get to production quicker,” explained Crain Construction.

The jobsite was located within close proximity to occupied offices. This tight footprint required innovative and detailed scheduling including just-in-time delivery for most materials. With limited storage space, large shipments were staged off-site and delivered to the worksite during low traffic. The entire Hilton Franklin Cool Springs project was completed in three phases over 20 months. To minimize disruption to the area’s office tenants, construction crews worked early mornings, nights and weekends, while adhering to noise restrictions.

Crain Construction noted the project’s success was a collaborative effort with the “developer, the design team and subcontractors, to meet stringent requirements and build a full-service hotel for developer Chartwell Hospitality that now serves as a prototype for full-service Hilton hotels.”

Hilton Franklin Cool Springs includes an upscale restaurant and bar, 5,600 square feet of meeting space, a 1,300-square-foot club lounge with an outside seating area and a second-floor heated pool. The rectangular structure is crowned with a flying roof that remains open above the club lounge terrace. At the street level, a cantilevered canopy covers the porte de’coche shading guests from the sun and protecting them from the weather.

Associated Builders and Contractors of Tennessee recognized the Hilton prototype and its team with an Excellence in Construction Award. In addition, the property and Chartwell Hospitality were honored with a Hilton Legacy Award for North America New Build of the Year. Hilton Franklin Cool Springs also earned AAA Four-Diamond status in 2019, an achievement that ranks the hotel among the top 6% of the more than 27,000 AAA-Inspected & Approved lodgings in North America.

Associated Builders and Contractors of Tennessee recognized the Hilton prototype and its team with an Excellence in Construction Award. In addition, the property and Chartwell Hospitality were honored with a Hilton Legacy Award for North America New Build of the Year. Hilton Franklin Cool Springs also earned AAA Four-Diamond status in 2019, an achievement that ranks the hotel among the top 6% of the more than 27,000 AAA-Inspected & Approved lodgings in North America.

The hotel is strategically positioned between two Class A office towers in Franklin’s Meridian Cool Springs Business District, a vibrant 60-acre mixed-use development. Nearby destinations include Historic Downtown Franklin, CoolSprings Galleria, the Charter House and Lotz House museums, and FirstBank Amphitheater presents concerts at Graystone Quarry. Approximately 20 miles from Nashville, Hilton Franklin Cool Springs is close enough to enjoy the city’s sights and sounds, while providing a productive workspace or relaxing retreat.

Hilton Franklin Cool Springs, 601 Corporate Centre Drive, Franklin, Tennessee 37067

- Owner/developer: Chartwell Hospitality; Franklin, Tennessee; https://www.chartwellhospitality.com

- Architect: Rabun Architects; Atlanta; https://www.rabunarchitects.com

- General contractor: Crain Construction; Nashville; https://crainconstructioninc.com

- Glazing contractor: McInerney and Associates; Nashville; https://www.mcinerneyassociates.com

- Manufacturer – aluminum-framed entrance and window wall systems: Tubelite; Walker, Michigan; https://tubeliteusa.com

- Finishing service provider – aluminum-framed entrance and window wall systems: Linetec; Wausau, Wisconsin

- Photographer: Andi Whiskey, Whiskey Media Studios

The post Hilton’s Southeastern hotel prototype showcases Linetec finishing and thermal improvement services on Tubelite window wall and entrances appeared first on Linetec.

Ferris State University’s Center for Virtual Learning and Esports Arena creates high-tech look with high-performance finishes by Linetec 18 Jul 2024, 1:46 pm

The newly constructed Center for Virtual Learning (CVL) at Ferris State University’s Big Rapids campus showcases technologically advanced classrooms, fully equipped 24-hour labs and the only purpose-built esports arena in Michigan. Opened in August 2023, the CVL offers an innovative, physical learning environment to envision and realize an interconnected virtual world.

Designed by Stantec, the project’s distinctive high-tech appearance and high-performance functionality features Tubelite 400TU Therml=Block® High Performance Thermal Curtainwall finished by Linetec in two colors – Arctic Ice and Grayish. Linetec also provided the aluminum framing’s thermal barrier system to improve energy efficiency and interior comfort on the CVL’s three-story, 64,000-square-foot facility.

Arctic Ice was selected for the majority of Tubelite curtainwall frames, such as for the first floor main entry and the third floor balcony enclosure. The Grayish color finish differentiates the curtainwall framing on the wall projections defining the second and third floors’ exteriors and adds visual interest within the overall glass and metal façade. Linetec applied durable two-coat, 70% PVDF resin-based architectural painted finishes. These coating systems meet the industry’s highest performance specification, AAMA 2605, published by the Fenestration and Glazing Industry Alliance.

Thermal Performance, Interior Comfort

Tubelite relies on Linetec as its single source solution for its finishing, thermal breaks and other value-added services – all under quality-assurance, factory-controlled conditions. Supporting the building’s energy efficiency and campus-wide sustainability goals, Tubelite 400TU Therml=Block curtainwall is designed to meet or exceed International Energy Conservation Codes, state building codes and other performance test standards.

For the CVL, Tubelite’s system features 1-inch insulating glass units, dual thermal strut framing and four-side pressure cap construction. To minimize unwanted heat transfer, the framing members’ interior and exterior surfaces are separated and insulated, helping maximize occupants’ comfort and minimize energy use.

Along with industry-leading thermal performance, Tubelite’s curtainwall met all the CVL’s project requirements for air, water, firestopping, acoustic, condensation resistance and structural criteria.

Physical Space, Digital Experience

The versatility of Tubelite’s system also helped achieve Stantec’s unique aesthetic design vision.