Add your feed to SetSticker.com! Promote your sites and attract more customers. It costs only 100 EUROS per YEAR.

Pleasant surprises on every page! Discover new articles, displayed randomly throughout the site. Interesting content, always a click away

Vulcan Tool Company

Vulcan Tool Company is a manufacturer of tube cutting machines: Brehm Tube Cutting Machines, Ringmaster Tube Cutting Machines, Ultimate Tube Cutting Machines, trim cutting machines with Shimmy Die Trim Tooling and Hydroform Trimming Machines, and Vulcanaire Grinding Attachment, Hydraulic Cylinder Repair, Welding and Fabrication and Precision Machining Services.Sales Engineer Job Description 17 Mar 2025, 3:12 pm

Sales engineer

Sales Engineer to promote and sell Tube Cutting Machinery and Trimming Dies

Primary Activity: Actively engage with potential and existing customers to promote and sell Vulcan Tool Company’s range of high-speed tube cutting machines and shimmy trim tooling.

Technical Expertise: Utilize experience with tube cutting applications and deep draw stamping to explain the technical specifications and benefits of our products and ensure customers grasp how our solutions can meet their specific needs.

Customer Relationship Management: Build on existing industry contacts involved in tube cutting applications and deep draw stamping operations to develop strong relationships with customers, provide exceptional service and support, and to foster long term partnerships.

Identify New Business Opportunities: Proactively identify and pursue new business opportunities with customers engaged in tube cutting applications and deep draw stamping operations.

Requirements:

- B.A. in Business Admin

- 24 months Exp. as sales engineer within the industrial or manufacturing sector

- Strong technical understanding of deep draw stamping & high speed tube cutting applications.

- Must be familiar with custom machine building

- Requires ability to develop solutions & convey complex technical information to customers.

Send Resume to info@vulcantoolcompany.com.

The post Sales Engineer Job Description appeared first on Vulcan Tool Company.

Vulcan Tool Company Earns ISO 9001:2015 & SDVOB Certification 10 Mar 2025, 2:31 pm

Vulcan Tool Company Earns ISO 9001:2015 & SDVOB Certification

Dayton, OH – March 10, 2025 – Vulcan Tool Company, operating under the legal entity Paradigm Industrial, is excited to announce its successful certification to the globally recognized ISO 9001:2015 standard. This certification demonstrates that the company’s management system meets the requirements for engineering services, precision machining, welding & fabrication, machine repair, and machine & die building. ISO 9001:2015 highlights Vulcan Tool Company’s commitment to delivering high-quality, consistent, and customer-focused solutions.

In addition to the ISO certification, Vulcan Tool Company is now recognized as a Service-Disabled Veteran-Owned Business (SDVOB) by the National Veteran Business Development Council (NVBDC). This certification acknowledges the company’s veteran leadership and further strengthens its commitment to excellence in manufacturing.

“Although the initiatives and procedures have had different names over the years, the Vulcan Tool Company has had a Quality Management System (QMS) ever since we entered the marketplace over a century ago. Now ANAB accredited Amtivo USA has certified that our QMS meets the ISO 9001:2015 standard. As Vulcan Tool Company continues to grow, this certification will make it easier for new customers to have confidence in our ability to meet their needs from the very beginning of our relationship.” said Ashley Webb, President at Vulcan Tool Company. “In addition to our commitment to quality, Paradigm Industrial LLC is our legal entity and was certified as a Service-Disabled Veteran Owned Small Business by the Small Business Administration several years ago. Recently, it was brought to my attention that many companies rely on the NVBDC to certify the status of Veteran business ownership. To meet these requirements for potential new customers and provide peace of mind for current customers who rely on Paradigm Industrial LLC dba Vulcan Tool Company to help fulfill contracting requirements, we went through the rigorous vetting process established by the NVBDC to confirm our status as a Service-Disabled Veteran Owned Business.”

These certifications further solidify Vulcan Tool Company’s standing as a trusted provider of precision-engineered solutions, making it easier to foster long-lasting relationships with new customers and continue delivering quality products and services.

About Vulcan Tool Company

Vulcan Tool Company, based in Dayton, Ohio, has been delivering high-quality precision machining, welding & fabrication, machine repair, and custom design & build solutions since 1916. Specializing in tube cutting machines, dies for trimming deep-drawn parts and end trimming, and grinding machines, Vulcan Tool Company serves customers in various industries across the U.S. and around the world. With a long history of excellence, Vulcan Tool Company continues to seek new opportunities and uphold its commitment to quality and customer satisfaction.

The post Vulcan Tool Company Earns ISO 9001:2015 & SDVOB Certification appeared first on Vulcan Tool Company.

Vulcanaire: A Jig Grinding Alternative 14 Feb 2025, 7:17 pm

Jig Grinding Alternative: A Cost-effective solution for precision grinding

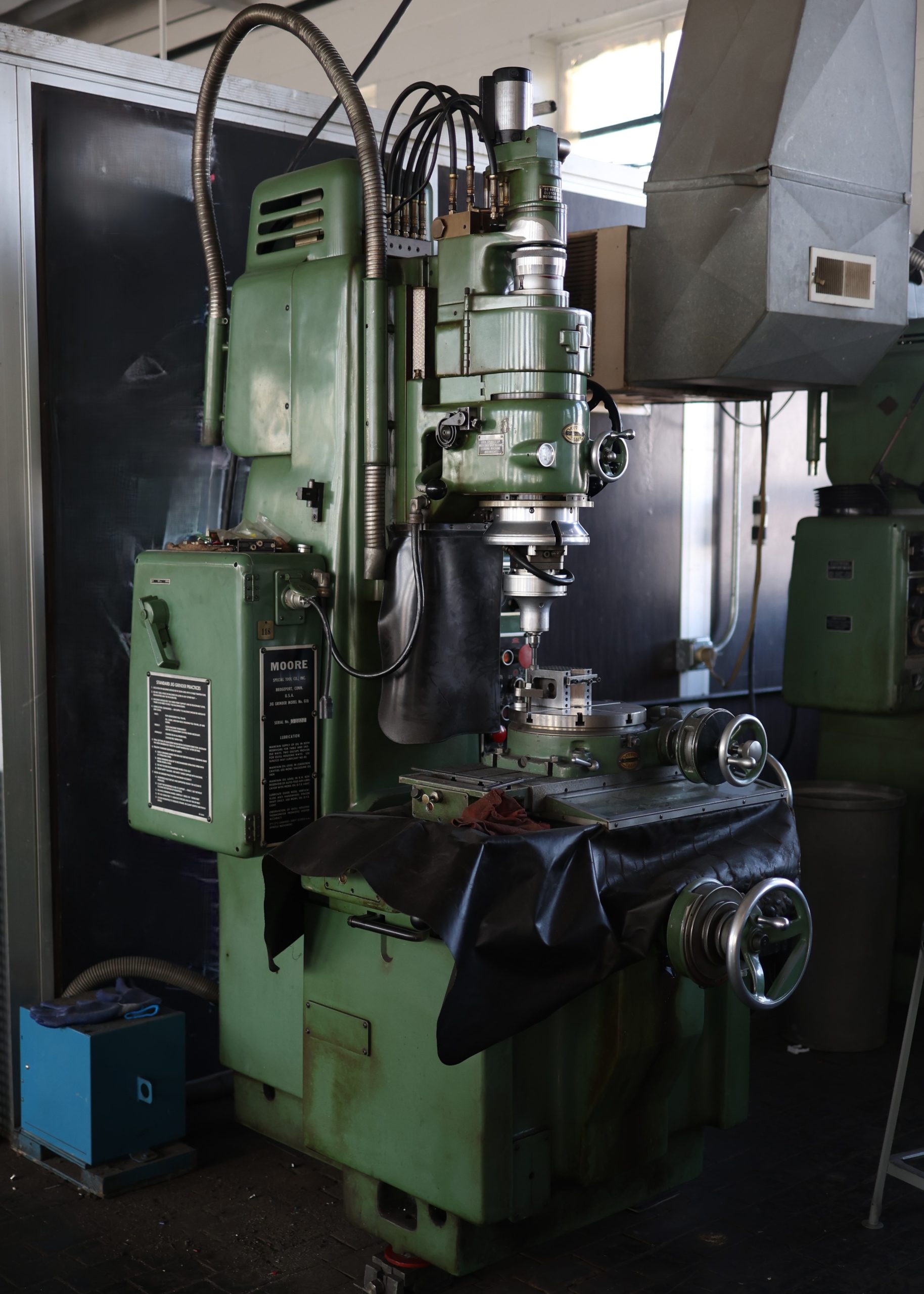

In the world of precision machining, jig grinders have long been the go-to solution for achieving ultra-precise hole grinding and finishing. However, the high cost and specialized nature of these machines make them impractical for many shops. Fortunately, there is a powerful jig grinding alternative that delivers comparable results at a fraction of the cost, the Vulcanaire Spindle Attachment, a high-precision grinding attachment that enhances existing equipment.

The Challenge: High Costs and Limited Accessibility of Jig Grinder

Jig grinders are highly specialized machines used for precision hole grinding and finishing, particularly in the aerospace, tool and die, and mold-making industries. While they offer unparalleled accuracy, their drawbacks include:

High Initial Investment

A dedicated jig grinder is expensive, making it a costly addition to most machine shops.

Specialized Training

Operating a jig grinder requires skilled technicians, adding to labor costs and training requirements.

Floor Space Requirements

As a standalone machine, a jig grinder takes up valuable shop space.

For many manufacturers, these limitations make it difficult to justify the purchase of a dedicated jig grinding machine. This is where the Vulcanaire Spindle Attachment provides an ideal alternative.

The Solution: Vulcanaire Spindle Attachment – A Versatile, High-Speed Grinding Option

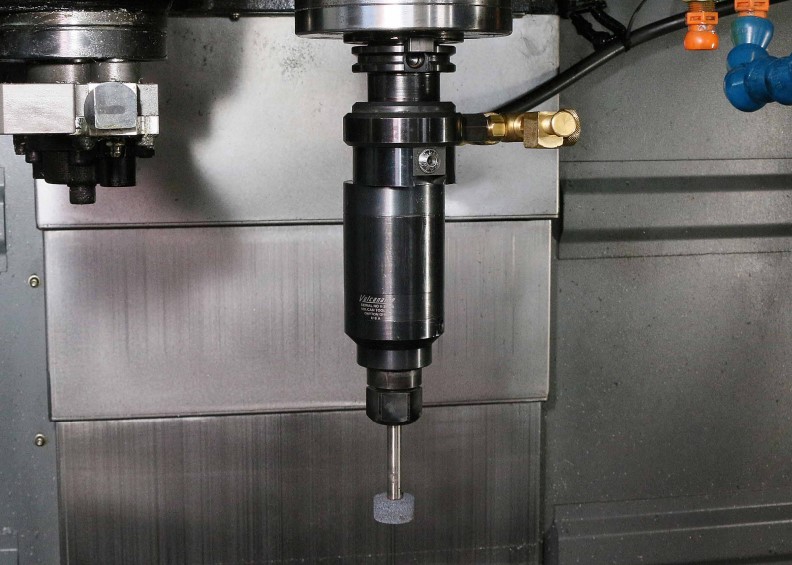

The Vulcanaire Spindle Attachment transforms your existing mill or lathe into a high-speed manual or CNC jig grinder capable of precision grinding. Designed as an affordable and efficient alternative to a dedicated jig grinder, the Vulcanaire grinding spindle attachment delivers key advantages:

Cost Savings

A fraction of the cost of a full jig grinder, making high-precision grinding more accessible.

High-Speed Performance

Spindle speeds ranging from 4,000 to 300,000 RPM, allowing for precision hole grinding and fine surface finishing.

Easy Integration

Mounts directly to milling machines, lathes, and other equipment, eliminating the need for an additional standalone grinder.

Versatility

Compatible with abrasive, carbide, CBN, and diamond wheels, allowing for a wide range of grinding applications.

Precision Capabilities

Achieves tolerances to tenths of a thousandth (0.0001”), delivering exceptional accuracy.

CNC Compatibility

Serves as a CNC spindle upgrade, transforming your equipment into a CNC jig grinder for automated, high-speed grinding.

Why Choose the Vulcanaire Over a Traditional Jig Grinder?

While jig grinders remain essential in some high-end applications, the Vulcanaire Spindle Attachment offers an attractive alternative for machine shops looking to expand their grinding capabilities without the high price tag. It allows manufacturers to:

Perform precision hole grinding without investing in a separate jig grinder.

Reduce setup time and increase shop efficiency by using existing equipment.

Maintain the flexibility to handle a variety of grinding tasks

including ID grinding and OD grinding. For those considering a jig grinding machine vs spindle attachment, the Vulcanaire provides a jig grinder alternative that offers both affordability and adaptability.

A Practical Choice for Precision Machining

For manufacturers in industries such as aerospace, tool and die, medical device production, and general machining, the Vulcanaire Spindle Attachment provides a practical and economical solution for achieving precision comparable to a jig grinder—at a fraction of the cost. With its ability to integrate seamlessly with mills and lathes, this high-precision spindle attachment for milling machines offers an unparalleled combination of affordability, precision, and versatility.

If your shop is looking for an affordable jig grinding solution that delivers high-precision results without the high costs, learn more about the Vulcanaire Spindle Attachment to see how this tool can enhance your machining capabilities.

Request a Quote or Consultation for Your Vulcanaire Spindle Needs!

The post Vulcanaire: A Jig Grinding Alternative appeared first on Vulcan Tool Company.

Vulcan Tool Company is Now ThomasNet Verified! 4 Feb 2025, 2:13 pm

Vulcan Tool Company is Proud to Announce We Are Now ThomasNet Verified!

We’re proud to announce that Vulcan Tool Company is now officially ThomasNet Verified! This recognition confirms our commitment to quality, reliability, and excellence in precision manufacturing. Being verified by ThomasNet reinforces our dedication to delivering high-quality products and services that meet the needs of our customers.

What Does This Mean for You?

As a ThomasNet Verified company, you can trust that we:

- Adhere to industry best practices

- Meet high standards of quality and safety

- Are reliable and accountable partners

- Have a strong reputation within our industry

This verification strengthens our commitment to offering you the best products and services, and we’re proud to be recognized for our continuous effort to improve and grow.

For more details, click here to visit our ThomasNet profile.

Thank you for your continued trust in Vulcan Tool Company

The post Vulcan Tool Company is Now ThomasNet Verified! appeared first on Vulcan Tool Company.

Visit us at Tube Dusseldorf 2024! 6 Mar 2024, 11:03 am

Visit Vulcan Tool Company

BOOTH E11-01/HALL 6

WIRE AND TUBE DUSSELDORF

APRIL 15TH-19TH, 2024

MESSE DUSSELDORF

STOCKNUMER KIRCHSTRAßE 61,

40474 DUSSELDORF, GERMANY

Learn about our Tube Cutting Machines

Vulcan Tool Company provides cutting equipment to customers around the world. Visit our booth at TUBE DUSSELDORF to learn more about our high speed Tube Cutting Machines with SHEAR SUPPORTED technology.

The Tube: The world’s leading trade fair for the tube industry

Over 1,000 exhibitors present their innovations along the entire value chain at the No. 1 trade fair for the tube industry: Tube showcases the entire spectrum – from raw materials to tube production, tube processing technology, tube accessories, tube trade, forming technology and machinery and equipment. Whether as an exhibitor, trade visitor or investor: the world’s most important tube trade fair in Düsseldorf is “the place to be” for central industries, trade, commerce and research. Make valuable contacts at the highest level, be inspired and take advantage of opportunities for new business.

The post Visit us at Tube Dusseldorf 2024! appeared first on Vulcan Tool Company.

We’re exhibiting at FABTECH 2023! Stop by booth D41838 to visit us! 17 Aug 2023, 1:28 pm

Visit Vulcan Tool Company

FABTECH Chicago

September 11-14, 2023

McCormick Place

2301 S King Dr

Chicago, Illinois

Learn about our Tube Cutting Machines and Shimmy Trim Dies for Deep Drawn Stampings

Vulcan Tool Company provides cutting equipment and trim tooling to customers in the United States and around the world. Visit our booth at FABTECH to learn more about our high speed Tube Cutting Machines and precision Shimmy Trim Dies.

Stop by booth D41838 to visit us! Because we’d love to see you at the show, we’re offering you a free expo floor pass – to attend as our guest!

The post We’re exhibiting at FABTECH 2023! Stop by booth D41838 to visit us! appeared first on Vulcan Tool Company.

Tube Cutting Machines Featured in Industry Journal 22 Mar 2023, 5:28 pm

The post Tube Cutting Machines Featured in Industry Journal appeared first on Vulcan Tool Company.

Trimming Prismatic & Cylindrical battery cell housings using a Shimmy Die 30 Nov 2022, 2:33 pm

As the world transitions to electric vehicles, the demand for batteries has skyrocketed in major automotive markets. With this increased demand, Vulcan Tool Company’s Shimmy Trim Die has provided manufacturers a way to be more efficient and reduce costs. These trimming processes have been refined over 70 years of Shimmy Die production. Vulcan Tool Company produces trimming solutions for deep drawn parts used in many industries, including aviation, medical, automobile, heavy vehicle, military, and household appliances. Decades of experience are now being used to provide trimming solutions for cutting edge battery production.

CYLINDRICAL BATTERY CELL HOUSING

Cylindrical battery cell housings have been popular for a variety of reasons. It is a simple, efficient and cost-effective design. Many applications rely on a high number of cells. The cylindrical shape of these battery cells provides strength that limits expansion that can occur as a result of extreme temperature and pressure changes. One of the first battery types to be created in large quantities, this kind is still quite popular.

There are benefits when using this type of housing for applications that require significant power. The compact design allows for many different storage configurations. Maintenance costs can also be reduced because faulty cells can be replaced individually. This proven technology has been used in some high profile electric vehicles like the Tesla Model S.

PRISMATIC BATTERY CELL HOUSING

Prismatic battery cell housings are made of carbon fiber, steel, aluminum, aluminum alloy or plastic and are designed to improve battery performance. Reliability increases because there are fewer connections in what is typically a larger housing. The housing size also helps reduce overall weight and improves battery pack efficiency.

This type of battery cell housing is becoming increasingly popular for a variety of reasons. They are strong and light, making them ideal for devices that need to be thin and where weight is an issue. They may also be modified to meet the requirements of a specific device. Producing fewer of the larger prismatic battery cells to achieve the same power output can make them more affordable.

The shape of prismatic battery cell housings allows them to be stored closely together. Power banks often use a number of prismatic cells. Some applications use cells that are interconnected by honeycomb-like channels. These channels help to protect the cells from damage caused by outside forces.

THE MAIN DIFFERENCES BETWEEN PRISMATIC AND CYLINDRICAL CELLS

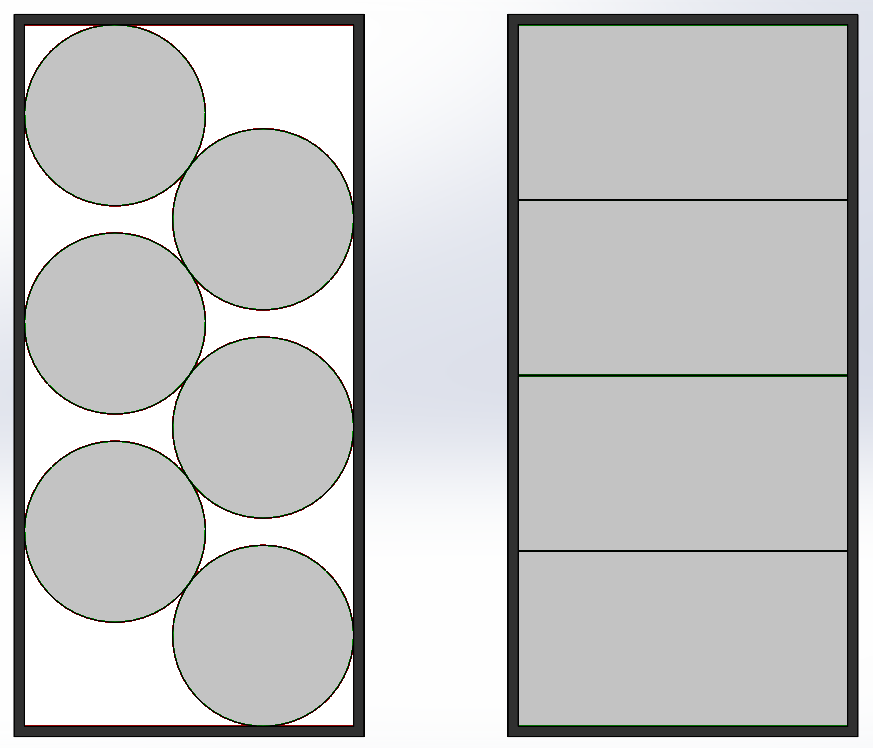

Packing principle for cylindrical cells (left) vs. the packing principle of prismatic and pouch cells (right).

Shape is not the only thing that differentiates prismatic and cylindrical cells. Other important differences include their space, power output, and cost

Space

Because of the round cross-section of the cylindrical cells, they are unable to completely utilize the space when assembled into packs and modules. The packaging density of cylindrical cells is consequently low. However, because of the space voids, coolant may more easily travel around the batteries in a pack, making thermal management of such packs simpler.

Power

Cylindrical cells may store less energy than prismatic cells, but they have more power. This means that cylindrical cells can release energy more quickly than prismatic cells. Due to this, prismatic cells are ideal to maximize energy efficiency while cylindrical cells are ideal for high-performance applications. Cylindrical cell applications are more reliable because when one cell goes bad in a battery built with Cylindrical Cells the effect is small whereas a Prismatic Battery would be left unusable in most cases.

Cost

Prismatic and Cylindrical battery cells are more suited for different chemical applications. Those most suited for Prismatic cells are less expensive initially, but have higher lifetime costs currently. With advancements in battery composition, this difference may change. At the moment, Cylindrical battery cell applications are typically less expensive over the life of the product.

MANUFACTURING AND TRIMMING OF THE PRISMATIC AND CYLINDRICAL BATTERY CELL HOUSINGS

The manufacturing of Prismatic and Cylindrical battery cell housings is intended to make the housing strong enough to protect the cells from physical damage and from the corrosive environment that the battery will be subjected to. It must also be able to withstand the high temperatures that the battery will experience.

A 3″ Shimmy Trim Die

Once the cell housing is drawn a transfer process is typically used to place the housing in a Shimmy Trim Die so it can be trimmed.

The Shimmy Die can trim an entire drawn part in one press stroke while controlling flatness and height. It can also trim with notches or irregular heights as needed. The master die can also be used with new tooling to trim other parts that are similar in size.

Brehm Shimmy Dies can be custom built to fit almost any application and to trim or profile any drawn shell to precision tolerances. Horizontal type dies can also be punch press driven which may become more economical for longer parts not suitable for vertical press orientation. Vertical dies can also be used with existing hydraulic or mechanical press for shorter tubular components or drawn stampings.

The post Trimming Prismatic & Cylindrical battery cell housings using a Shimmy Die appeared first on Vulcan Tool Company.

Vulcan Tool Awarded Grant to Promote Manufacturing Explorer Post 5 Oct 2022, 2:33 pm

$1,000 Grant Intended to Encourage Manufacturing Explorer Post Participation

$1,000 Grant Intended to Encourage Manufacturing Explorer Post Participation

The Precision Metalforming Association Educational Foundation announced this week that Vulcan Tool Company has been awarded a grant through the foundation’s Micro-Grant Program. The Micro-Grant Program is designed to help PMA member companies build a talent pipeline, and positively impact their community. PMAEF allocated $15,000 for the Metalforming Micro-Grant Program to foster the growth and promotion of metalforming careers and initiatives. The program aims to provide funding to member companies that implement projects or programs to enhance the public’s experience and exposure to manufacturing/metalforming careers in collaboration with MFG Day initiatives.

Vulcan Tool Manufacturing Day Open House

Vulcan Tool Manufacturing Day Open House

Manufacturing Day is the first Friday in October. Vulcan Tool Company’s open house is the night prior on Thursday, October 6, from 6-9 pm. During the open house visitors will have an opportunity to participate in hands on activities to help them better understand what it is like to work in a modern manufacturing environment. A chili dinner will be served and guests can learn about how prospective youth members and adult volunteers can be a part of the Manufacturing Explorer Post. All ages are invited to participate!

About Our Manufacturing Explorer Post

About Our Manufacturing Explorer Post

Exploring is a unique career exploration program for young men and women ages 14—20. Our program provides students with an opportunity to learn about manufacturing career fields and network with professionals already working in those fields. The wide variety of work done by Vulcan Tool Company makes it an ideal place for young people interested in skilled trades to come to learn more about career path options in manufacturing. Engineering, machining, welding, machine repair, machine building, and controls & automation are all part of the work done at Vulcan Tool on a daily basis.

Get Your Free Ticket for the Open House Here

The post Vulcan Tool Awarded Grant to Promote Manufacturing Explorer Post appeared first on Vulcan Tool Company.

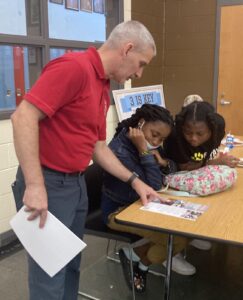

Vulcan Tool Visits Local High Schools 2 Oct 2022, 1:30 am

Promoting Open House and New Manufacturing Explorer Post

Promoting Open House and New Manufacturing Explorer Post

Vulcan Tool Company President Ashley Webb visited local high schools recently to invite students to visit during the upcoming Open House event and promote the new Manufacturing Explorer Post. This past week he visited both the Dayton Regional STEM School and Belmont High School. Invitations have been extended to nearly two dozen high schools and career tech programs in the Miami Valley, encouraging students to consider attending October 6th Open House.

Vulcan Tool Manufacturing Explorer Post Provides Skilled Trades Insights

Vulcan Tool Manufacturing Explorer Post Provides Skilled Trades Insights

Exploring is a unique career exploration program for young men and women ages 14—20. Our program provides students with an opportunity to learn about manufacturing career fields and network with professionals already working in those fields. The wide variety of work done by Vulcan Tool Company makes it an ideal place for young people interested in skilled trades to come to learn more about career path options in manufacturing. Engineering, machining, welding, machine repair, machine building, and controls & automation are all part of the work done at Vulcan Tool on a daily basis.

Going to College to be an Engineer? EXPLORING IS FOR YOU TOO!

Going to College to be an Engineer? EXPLORING IS FOR YOU TOO!

Exploring Manufacturing Careers includes direct application of mechanical and electrical engineering skills. We also touch on architectural, structural and civil engineering concepts as we learn how industry finds solutions to become more efficient and productive. Anyone who is interested in a career in manufacturing can learn more by participating in our Explorer Post!

Get Your Free Ticket for the Open House Here

The post Vulcan Tool Visits Local High Schools appeared first on Vulcan Tool Company.