Add your feed to SetSticker.com! Promote your sites and attract more customers. It costs only 100 EUROS per YEAR.

Pleasant surprises on every page! Discover new articles, displayed randomly throughout the site. Interesting content, always a click away

Monroe Fluid

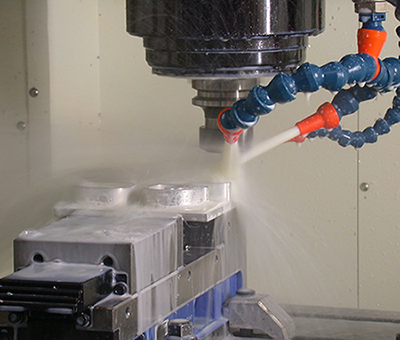

Your Single Source Supplier of a complete range of metalworking fluids, industrial cleaners and rust preventatives.Basic Coolant Categories 6 Aug 2024, 5:47 pm

Basic Coolant Categories

What You Need To Know

Semi-Synthetics & Micro Emulsions:

Have less than 30% mineral oil content in concentrate & the concentrate contains water. Dilution appears translucent.

One of the benefits is short term rust protection as the coolant leaves an oily film on parts. Products reject tramp oils effectively, and the emulsions are very stable and long-lasting. Better cooling allows higher cutting speeds and they combine the best features of synthetics and soluble oils.

Semi-synthetic emulsions provide micro-sized oil droplets, beneficial in single-point turning applications that require optimal cooling with less lubrication.

Our semi-synthetics are perfect for powdered metals that produce sand-like swarf instead of chips, preventing filter clogging and sump clinker formation. They are also excellent for cast iron machining, sawing and grinding applications.

Semi-synthetic coolants excel in cleanliness and workpiece visibility.

Soluble Oils:

These products were the first generation of “coolants” and because of their many advantages, they are still in use today. Over the years, many enhancements have been formulated into these products like extended sump life and low foam for high pressure applications.

- Composition: Contains more than 30% mineral oil and no water in concentrate. When diluted, they have a milky appearance rather than a translucent one.

- Cost Efficiency: More economical than straight or neat oils, as they can be diluted with water, reducing costs without significantly compromising tooling effectiveness.

- Cooling Efficiency: Soluble oils provide 2 to 3 times better cooling than straight oils.

- Versatility: Their emulsions are highly versatile and suitable for most machining and grinding applications across a wide range of materials.

- Health and Safety Benefits: Compared to straight oils, soluble oils offer improved health and safety in the shop environment, with no fire hazard and reduced oil misting and fogging.

- Ease of Management: Among water-extendable metal removal fluids, soluble oils are the most forgiving when it comes to concentration fluctuations and poor management.

- Residue Characteristics: The residues left by soluble oils are generally oily and not sticky.

Neat Oils:

Primarily composed of naphthenic or paraffinic base oils, neat oils contain extreme pressure additives like chlorine, sulfur, and fats. They do not emulsify with water and do not contain any water. Neat oils are typically used in Swiss-style screw machines, deep/gun drilling, EDM, threading, and grinding applications.

Synthetic Coolants:

Do Not Contain Any Mineral Oil. Synthetics provide:

- Rapid heat dissipation

- Excellent workpiece visibility

- Total rejection of tramp oils possible

- Usually easy to measure and control concentration. Bacterial attack may be easier to control

- Stable and potentially long-lasting

- No oil mist problem; no oil disposal concerns

- Easily filtered

- Recycling or reclaiming is usually highly effective

- Low consumption due to the fact that synthetics are true solutions with no droplet formation adding to carry off issues

Selecting the Right Coolant

If you have questions, consult with our technical team for assistance.

The post Basic Coolant Categories appeared first on Monroe Fluid.

Factors to Consider When Choosing A Hydraulic Fluid 8 Jul 2024, 6:19 pm

Factors to Consider When Choosing A Hydraulic Fluid

Hydraulic Systems

A good hydraulic fluid is essential for the efficient and reliable operation of hydraulic systems. Here are the top five characteristics of a good hydraulic fluid.

Viscosity:

- Stability: The viscosity should remain stable across a wide range of temperatures to ensure consistent performance.

- Optimal Viscosity: It should be neither too thick (causing resistance and inefficiency) nor too thin (leading to inadequate lubrication and sealing).

Lubricating Ability:

- The fluid should provide excellent lubrication to reduce friction and wear on moving parts within the hydraulic system.

- Proper lubrication helps in extending the lifespan of components and maintaining system efficiency.

Thermal Stability:

- The fluid should resist breakdown or degradation at high temperatures.

- It should maintain its properties and performance even under extreme operating conditions, preventing sludge formation and deposits.

Oxidation Resistance:

- Good hydraulic fluid should resist oxidation, which can lead to the formation of acids, sludge, and varnish.

- Oxidation resistance extends the fluid’s service life and protects the hydraulic system from corrosion and deposits.

Water Tolerance & Demulsibility:

- The fluid should have the ability to tolerate small amounts of water without losing performance or causing corrosion.

- Good demulsibility is important to separate water from the fluid quickly, preventing water contamination and related issues such as rust and reduced lubrication.

Selecting the Right Hydraulic Fluid

Additional important characteristics include anti-wear properties, corrosion inhibition, and compatibility with system materials. Selecting the right hydraulic fluid involves balancing these characteristics to match the specific requirements of the hydraulic system in use. If you have any questions, consult with our technical team for assistance.

The post Factors to Consider When Choosing A Hydraulic Fluid appeared first on Monroe Fluid.

Environmental Concerns and Responsibilities for Liquid Waste Streams 14 May 2024, 6:06 pm

Environmental Concerns and Responsibilities for Liquid Waste Streams

Our friends at Twin Specialties/Gemini Disposal in Blue Bell, PA are a distributor of Monroe Fluid Technology products. They offer a wide range of products including Metalworking Fluids, Industrial Lubricants, Industrial Cleaners, Rust Preventatives, Greases, Absorbents Chemicals, Specialty Lubricants and Automotive Products. Their Gemini Disposal Division serves the Mid-Atlantic area (PA, NJ, DE, MD, NY) and they remove waste oil, oil water, and other industrial waste. Thanks to Matt Petrosky for allowing us to share this information. A clean environment is in all of our best interests.

How Liable Are You as the Generator of a Liquid Waste Stream?

The liability of the generator of a liquid waste stream can vary depending on various factors including the type of waste, applicable regulations, and the circumstances surrounding its generation and disposal.

Here Are Some Common Liabilities Associated with Waste Generators:

- Environmental Liability: Generators can be held liable for any environmental damage caused by improper disposal or mishandling of liquid waste. This can include contamination of soil, groundwater, or surface water bodies, which may result in cleanup costs and legal penalties.

- Regulatory Compliance: Generators are typically responsible for complying with relevant environmental regulations governing the handling, storage, transportation, and disposal of liquid waste. Failure to meet these requirements can lead to fines, penalties, and legal actions.

- Health and Safety Liability: Improperly managed liquid waste can pose risks to human health and safety, both for workers handling the waste and for the surrounding community. Generators may be liable for any harm or accidents resulting from inadequate safety measures or exposure to hazardous waste.

- Contractual Liability: If a generator contracts with third-party waste management companies for disposal services, they may have contractual obligations regarding proper waste handling and disposal. Failure to fulfill these obligations can lead to contractual disputes and liabilities.

- Financial Liability: Generators may bear financial responsibility for the costs associated with proper waste management, including collection, treatment, transportation, and disposal fees. Additionally, they may be liable for any damages or cleanup costs resulting from spills or contamination.

Effective Waste Management Practices

To mitigate these liabilities, generators should implement effective waste management practices, including proper labeling, storage, and disposal procedures, as well as compliance with applicable regulations and industry standards. Regular monitoring, training, and audits can help ensure compliance and minimize risks associated with liquid waste generation.

Questions? Want to Learn More?

The post Environmental Concerns and Responsibilities for Liquid Waste Streams appeared first on Monroe Fluid.

The Reusable Packaging Revolution: Collaborating for Sustainability 12 Apr 2024, 3:34 pm

The Reusable Packaging Revolution: Collaborating for Sustainability

Sustainability

In recent years, sustainability has emerged as a critical focus across industries worldwide. From reducing carbon footprints to minimizing waste, businesses are increasingly recognizing the importance of adopting eco-friendly practices. One area that has seen significant attention is packaging, with a growing emphasis on reusable solutions to tackle the mounting issue of single-use plastics. The journey towards a sustainable future in packaging is paved with collaboration and shared systems, as highlighted in a recent article by Pack World.

About the Article

The article underscores the necessity of collaboration among stakeholders to drive the widespread adoption of reusable packaging. It emphasizes the importance of building shared systems that facilitate the efficient use and circulation of reusable packaging materials. This collaborative approach involves not only businesses but also policymakers, consumers, and packaging manufacturers working together towards a common goal of sustainability.

One key aspect highlighted in the article is the role of technology in enabling reusable packaging systems. Advanced tracking and monitoring technologies, such as RFID tags and blockchain, play a crucial role in managing reusable packaging assets throughout their life cycle. These technologies provide valuable insights into the movement and utilization of packaging materials, helping optimize their usage and minimize losses.

Moreover, collaboration between businesses is essential for scaling up reusable packaging initiatives. By forming partnerships and alliances, companies can leverage each other’s strengths and resources to overcome common challenges associated with implementing reusable packaging solutions. This collaborative approach fosters innovation and accelerates the adoption of sustainable practices across industries.

The article also stresses the significance of consumer education and engagement in driving the demand for reusable packaging. By raising awareness about the environmental impact of single-use plastics and highlighting the benefits of reusable alternatives, businesses can empower consumers to make informed choices. Additionally, incentivizing consumers to participate in reuse programs can further encourage the widespread adoption of sustainable packaging solutions.

Furthermore, policymakers play a crucial role in creating an enabling environment for reusable packaging initiatives. Through regulatory frameworks and incentives, governments can incentivise businesses to invest in reusable packaging solutions and establish standards for their implementation. Additionally, policymakers can support research and development efforts aimed at enhancing the efficiency and scalability of reusable packaging systems.

Create A More Sustainable Future for Packaging

In conclusion, the transition towards a circular economy in packaging requires collaboration and shared systems across multiple stakeholders. By working together, businesses, policymakers, consumers, and packaging manufacturers can drive the reusable packaging revolution forward. Embracing innovative technologies, fostering partnerships, and educating consumers are essential steps towards creating a more sustainable future for packaging. As we navigate the challenges of sustainability, collaboration remains the cornerstone of achieving lasting change in the packaging industry.

Questions? Want to Learn More?

The post The Reusable Packaging Revolution: Collaborating for Sustainability appeared first on Monroe Fluid.

Mist Mitigation: Protecting Your Employees’ Health, Protecting The Air We All Breathe 27 Feb 2024, 7:54 pm

Mist Mitigation: Protecting Your Employees’ Health, Protecting The Air We All Breathe

This blog post was written by our friend Rosemary Panici of 3nineUSA, Inc.

Why 3nine?

When choosing an oil mist collector, it is important to consider several key features to ensure that it is effective and sustainable. CNC operators are exposed to oil mist with contaminants generated by metalworking fluids and oils, which can cause serious health issues such as eye, nose, and throat irritation, as well as respiratory problems like chronic bronchitis or COPD. Long-term exposure can also lead to heart attacks and arrhythmias in people with heart disease. Therefore, removing oil mist is not just important but a critical step for workplace safety, cleanliness, and environmental protection.

3nine was founded in Sweden to address the oil mist problems of the metalworking industry. When it comes to achieving pristine industrial air quality, there are two options: separation technology and traditional filter-based collection methods. 3nine has been a pioneer in this field for over two decades, and we firmly believe that the superiority of our groundbreaking approach to separating particles instead of merely collecting them in filters is transforming industries worldwide.

The 3nine US office has been offering reliable solutions to the North American Metal metalworking industry since 2009, effectively addressing their oil mist problems. Our innovative technology, based on disc stack separation, delivers unparalleled purification with minimal maintenance. Our technology guarantees clean air at the lowest total cost of ownership. For over a decade, 3nine has been making significant strides in disc stack separation, acquiring over 100 global patents.

Separation Technology’s Precision

In an era where precision and efficiency reign supreme, separation technology is a testament to innovation. Unlike conventional filter-based methods that simply collect particles in a filter media, our approach directly separates oil mist, dust, and particles from the airflow. The advantages are undeniable:

- Elevated Efficiency: Our separation technology does not just clean the air; it does so with unparalleled efficiency. Preventing particles from infiltrating vital machinery not only ensures cleaner air but also extends the lifespan of equipment, minimizing costly downtime.

- Sustainability at Its Core: Beyond cleaner air, the separated particles can be recycled, aligning with sustainability goals, and minimizing waste.

- Cost-Effective Longevity: While the initial investment may be marginally higher, the long-term savings are substantial. Reduced filter replacements, less downtime, and lower maintenance requirements translate to improved cost efficiency.

Filter-Based Collection Challenges

Filter-based collection methods have long been the bedrock of air purification, offering reliability and familiarity. Yet, as industries evolve, this method faces challenges:

- Maintenance Demands: Filters require regular maintenance and replacements, increasing operational costs over time.

- Diminished Efficiency: As filters accumulate particles, their efficiency diminishes, potentially affecting air quality and equipment performance.

3nine’s Permanent Media

Many competing filtered technologies suggest a higher flow rate (CFM/m3/h) than 3nine, simply because they need to do so. Mechanical solutions, for instance, require 3-4 times more CFM/m3/h due to their filters and longer pipe runs, which ultimately lead to pressure drops. Four main factors, namely filters, contaminants, airflow, and viscosity, contribute to pressure drop. Technologies that rely on filters require multiple filter changes, as filters get saturated, leading to pressure drops that necessitate more CFM when using other technologies compared to 3nine.

3nine’s permanent media eliminates pressure drop, resulting in high efficiency, as none of the processed air is pulled through a filter. It’s easy to determine the CFM/m3/h you need for your machine tool with 3nine. Simply measure the cubic footage/cubic meters (WxDxH) of the cabin, and then refer to the unit specifications to determine the maximum cabin size that each oil mist collector can handle.

Oil mist can cause damage to your electrical equipment, circuit boards, and machine tools. It can also contaminate the components of your CNC machines, reducing efficiency and creating a potential fire risk. To prevent these issues, 3nine offers a unique solution. Our permanent media cleans to 1 micron before passing through a final stage HEPA filter, delivering consistently clean air that is 99.9% free from mist and smoke fumes. In contrast, typical mist collection systems only clean to 3-micron. Our H13 HEPA filter ensures that our cleaning process goes down to .03 microns, which is much more effective.

It’s important to note that not all HEPA filters are created equal. That’s why 3nine uses only Freudenberg grade H13 HEPA filters, which are designed specifically for mist applications. These filters can last up to 18,000 hours, much longer than other filters. Moreover, all Freudenberg HEPA filters are certified and undergo integrity tests, ensuring high quality and reliability.

HEPA filters are classified from H10 to H12, but those considered medical grade fall under the H13 category. They are often used in hospitals and are known to be the most effective method of air filtration. One satisfied customer claimed that their filter lasted for 3.5 years, running 24/7. With 3nine, replacing the HEPA filter is quick and easy. All it takes is four quick-release latches, and no tools are required.

3nine has developed and patented an automated cleaning system known as CIP, or Clean In Place. This system uses a pump and a timer that utilizes oil or coolant from the clean side of your machine tool’s sump. The CIP sprays a 4-second blast of fluid on the disk stack and rotor approximately every 10 minutes to clean it, maintaining separation efficiency without any human intervention. This results in minimal maintenance requirements and consistently high efficiency in purifying the air.

If you want to maintain the efficiency of your machinery, it is important to perform maintenance according to the manufacturer’s recommendations. These recommendations may differ depending on the technology used, but in all cases, maintenance is usually required several times a year.

Our mission is to revolutionize the CNC Machining, Grinding, Swiss-type machining, and metalworking industry while providing 99.9% clean air, keeping sustainability, cost-effectiveness, and efficiency in mind. Our vision is Clean Air for everyone! Our innovative technology provides the lowest total cost of ownership.

The post Mist Mitigation: Protecting Your Employees’ Health, Protecting The Air We All Breathe appeared first on Monroe Fluid.

Extend Your Coolant Life With Simple Maintenance Tips 1 Feb 2024, 12:30 pm

Extend Your Coolant Life With Simple Maintenance Tips

Charging A Machine Sump

When charging a machine sump, make sure the sump is clean. Adding new coolant on top of old coolant remnants is a bad practice. If you don’t have a lot of time to tear down a system for a deep clean, you can use a sump cleaner on top of your old coolant like our Astro-Clean A. Add 3-5% of sump volume, run for a min. of 24 hours, then dump, rinse and recharge.

Frequent checks of the coolant concentration (several times per week) using a refractometer is probably the best thing you can do to maintain coolant quality. You can use our Coolant Calculator on our website, to convert your brix reading to percentage. Takes a minute or two to do; can save you significant money on tooling, coolant costs and you’ll get better finishes. In addition high concentrations can have a negative effect on your operators, plus it’s just a waste of money with no gain in efficiency.

Tramp oil removal is also a key. Tramp oil can be the cause of “Monday Morning Odor”

and it also breaks down the coolant. Simple fixes: use an oil skimmer or a shop vac to pull off tramp oil off the surface of the sump. Install an oxygenator or a simple fish tank bubbler to aerate and keep the tramp oil from forming a barrier layer.

Coolant Calculator

There are a lot of resources on our web site, including a short (30 sec) video of how to use the Coolant Calculator. If you have any questions, feel free to reach out to us. You can speak with our lab team and they can help. They all have extensive field/practical experience, so if you have a question or problem, they have probably seen it before. We are all here to do our best for our customers.

Questions about Our Coolant Calculator? Want to Learn More?

The post Extend Your Coolant Life With Simple Maintenance Tips appeared first on Monroe Fluid.

Possible Price Instability In Base Stocks Caused By Shipping Chokepoints 19 Jan 2024, 4:36 pm

Possible Price Instability In Base Stocks Caused By Shipping Chokepoints

Shipping Issues & Market Impact

The shipping problems in key maritime routes like the Suez Canal and Panama Canal can have an impact on the petroleum market and, consequently, petroleum-based stocks.

Here Are Some Potential Effects:

- Supply Disruptions: If a shipping bottleneck occurs in these canals, it can disrupt the transportation of oil and other petroleum products. This can lead to delays in deliveries, affecting supply chains and potentially causing shortages.

- Shipping Costs: Increased congestion or delays in these major shipping routes may lead to higher shipping costs. Oil companies and refineries could face increased transportation expenses, impacting their overall costs and profit margins.

- Oil Prices: Supply disruptions and increased costs can contribute to changes in oil prices. If there are concerns about reduced supply due to shipping issues, it could lead to an increase in oil prices. Conversely, if the market perceives that the issues are temporary, the impact on prices may be limited.

- Stock Market Volatility: Companies involved in the petroleum industry, including those engaged in exploration, production, refining, and transportation, may experience increased stock market volatility. Investors often react to uncertainties and disruptions in the supply chain.

- Global Economic Impact: The movement of oil is crucial for the global economy. Any disruptions in shipping routes can have broader economic consequences, potentially affecting various industries and markets around the world.

Specific Impact Can Vary

It’s important to note that the specific impact can vary depending on the duration and severity of the shipping problems, as well as other geopolitical and economic factors at play. Investors and industry analysts closely monitor such events for potential market implications.

Questions? Want to Learn More?

The post Possible Price Instability In Base Stocks Caused By Shipping Chokepoints appeared first on Monroe Fluid.

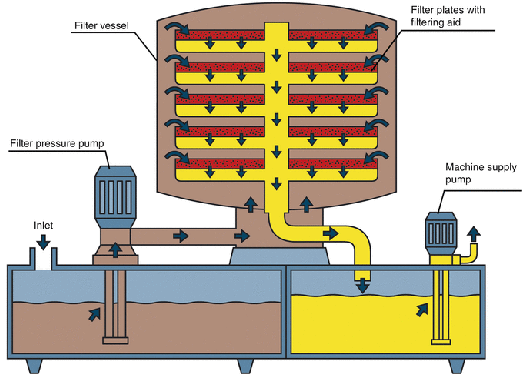

Filtration and Maintaining Coolant Quality 29 Nov 2023, 7:14 pm

Filtration and Maintaining Coolant Quality

Maintain & Improve Coolant Quality

Filtration is crucial in metalworking coolant systems to maintain and improve coolant quality for several reasons:

1. Particle Removal: Metalworking processes often generate particles, such as chips, fines, and abrasive particles, that can contaminate the coolant. Filtration helps remove these particles, preventing them from circulating in the coolant and causing damage to machinery, tooling, and workpieces.

2. Tool & Machine Protection: Contaminants in the coolant can lead to increased tool wear and damage to machining equipment. Filtration helps protect cutting tools, grinding wheels, and other machinery components by removing debris that could otherwise cause premature wear and reduce tool life.

3. Surface Finish & Dimensional Accuracy: Clean coolant contributes to better machining performance, resulting in improved surface finish and dimensional accuracy of the machined parts. Contaminants in the coolant can adversely affect the quality of the finished product.

4. Cooling Efficiency: Filtration helps maintain the thermal properties of the coolant. Clean coolant is more efficient at dissipating heat generated during metalworking processes. Efficient cooling is essential to prevent overheating of tools and workpieces, which can affect the machining process and the quality of the final product.

5. Extended Coolant Life: Filtration helps extend the life of the coolant by removing contaminants that can contribute to coolant degradation. Clean coolant lasts longer and requires less frequent replacement, reducing maintenance costs.

6. Corrosion Prevention: Metalworking coolants are susceptible to corrosion, especially in the presence of contaminants. Filtration helps reduce the likelihood of corrosion by removing particles and impurities that can contribute to the breakdown of the coolant’s corrosion inhibitors.

7. Improved Cutting Fluid Performance: In addition to removing particulate matter, filtration can also help maintain the chemical stability of cutting fluids by removing contaminants that may react with the fluid components. This contributes to the overall effectiveness of the cutting fluid in the metalworking process.

8. Environmental & Health Considerations: Filtration aids in meeting environmental and health regulations by reducing the discharge of contaminated coolant into the environment. Proper filtration can help industries adhere to environmental standards and ensure a safer working environment for operators.

In No Particular Order, Here Are 5 Coolant Filtration Companies:

(We do not sell any filtration equipment nor is there any consideration for the following mentions.)

- Hydro Engineering, Inc.: hydroblaster.com

- The Hilliard Corporation: hilliardcorp.com

- Sunnen Products Company: sunnen.com

- TBH North America: tbh.eu/us.html

- Industrial Fluid Systems, Inc.: industrialfluidsystems.com

Questions? Want to Learn More?

The post Filtration and Maintaining Coolant Quality appeared first on Monroe Fluid.

12 Factors To Consider About Technical Education 23 Oct 2023, 3:32 pm

12 Factors To Consider About Technical Education

Monroe Fluid Technology EDU Program

Trade school education offers many benefits for individuals who are looking for career-focused training and a path to gainful employment. Monroe Fluid Technology EDU program is focused on supporting students and schools providing the necessary training in the metalworking industry.

Here Are Some of The Key Benefits of Trade School Education:

- Career-Focused Training: Trade schools offer specialized training programs that are designed to prepare students for specific careers in industries such as automotive technology, healthcare, construction, culinary arts, and more. This focused training allows students to acquire the skills and knowledge needed for their chosen profession quickly.

- Shorter Duration: Trade school programs are typically shorter in duration compared to traditional four-year college degrees. Most programs can be completed in one to two years, enabling students to enter the workforce sooner and start earning a salary.

- Cost-Effective: Trade school education is often more affordable than a traditional college or university education. Students can save money on tuition and living expenses, and some programs offer financial aid or scholarships to help further reduce costs.

- High Demand for Skilled Workers: Many trade professions are in high demand, and the skills acquired in trade schools are often immediately applicable in the job market. This can lead to quicker job placement and opportunities for career advancement.

- Hands-On Learning: Trade school programs emphasize hands-on training, allowing students to gain practical experience in their field. This approach helps them develop the skills and confidence needed to excel in their careers.

- Specialized Skills: Trade schools teach specific skills that are relevant to a particular industry. This specialization can make graduates more attractive to employers looking for candidates with the exact skills they need.

- Industry Connections: Many trade schools have strong relationships with local businesses and employers. This can lead to internship opportunities, job placement assistance, and networking opportunities for students.

- Flexibility: Trade schools often offer flexible class schedules, including evening or weekend classes, to accommodate students who may be working or have other commitments.

- Certification and Licensing: Many trade school programs prepare students for industry certifications and licensing exams. Earning these credentials can enhance job prospects and earning potential.

- Job Security: Trade professions often provide job security because they are essential to the functioning of various industries. Skilled trade workers are less likely to be outsourced or replaced by automation.

- Competitive Wages: Graduates of trade schools can earn competitive wages, especially as they gain experience and expertise in their field. Some trade professions offer the possibility for high earning potential.

- Opportunity for Entrepreneurship: With the skills and knowledge gained in trade school, individuals may choose to start their own businesses or work as independent contractors in their field, offering opportunities for entrepreneurship.

Monroe Fluid Technology Believes That Education Is A Key to Success

Trade school education offers a cost-effective, efficient, and career-focused path to acquiring practical skills and entering the workforce in high-demand industries. The metalworking industry has a high demand for cnc operators and programmers. Trade School education can be an excellent choice for individuals who want to pursue a specific career and start working sooner rather than spending several years in a traditional college or university setting. Many schools offer associate degrees that can be used to acquire a bachelor’s degree if desired. Monroe Fluid Technology believes that education is a key to an individual’s success and leads to an increase in benefits to our society as a whole.

Questions? Want to Learn More?

The post 12 Factors To Consider About Technical Education appeared first on Monroe Fluid.

Climate Neutral—Our Commitment 14 Aug 2023, 11:09 am

Climate Neutral—Our Commitment

Monroe Fluid Technology Continues Commitment to Sustainability

“It’s a challenge running a company that utilizes petrochemicals, but we are doing our best to offset that by investing in clean energy and sustainability initiatives in under-developed countries,” according to CEO Alan Christodaro.

“We feel it’s important to participate in these efforts, and we are again purchasing carbon offsets in 2023-2024.” The credits purchased this year will support wind generated electricity and a project to capture and utilize methane.

Monroe Fluid Technology has implemented energy-saving programs throughout the manufacturing facility and changed packaging that allows for easier recycling and repurposing. The installation of passive solar technology is also being researched as part of the commitment to creating a cleaner environment.

The post Climate Neutral—Our Commitment appeared first on Monroe Fluid.