Add your feed to SetSticker.com! Promote your sites and attract more customers. It costs only 100 EUROS per YEAR.

Pleasant surprises on every page! Discover new articles, displayed randomly throughout the site. Interesting content, always a click away

SMART Safety Group – Pacific Coast Operations

Sending Workers Home Safely Every Day!National Safe Digging Month 18 Apr 2022, 6:12 pm

‘Tis the season…to get outside and prepare your yard for warmer weather. Before you start digging, don’t forget to locate underground utilities. April is National Safe Digging Month and it’s a great reminder to “call before you dig.” No matter how small the project, digging without confirming the location of underground utilities is dangerous and could result in serious injury, death, service disruptions, and costly repairs to utility lines. In fact, many utilities are buried just a few inches below ground. It is quick and easy to have buried utilities marked with paint or flags so that you don’t unintentionally dig into an underground utility line.

All you have to do is “call before you dig.” A few days prior to digging, you can call 811 or go online to call811.com and request to have utility companies send out locators who will come to your dig site and mark the approximate location of buried utilities. These markers greatly reduce the chance of inadvertently digging into buried utility lines and help you protect yourself and your community.

The post National Safe Digging Month appeared first on SMART Safety Group - Pacific Coast Operations.

Construction Workers at Highest Risk of Traumatic Brain Injury on the job 7 Mar 2022, 1:44 pm

The hard hat is the defining symbol of the construction industry and for good reason. While there are numerous safety tools and devices, few are as important as the hard hat. Hardhats are the leading preventer of Traumatic Brain Injuries, which are more common amongst construction workers than any other industry. A traumatic brain injury is a head injury that causes damage to the brain by an outside force, often causing long term complications or death. While proper use of hardhats can certainly aid in preventing such injuries, PPE is the least preferred method of hazard control. The best way to prevent head injury is to eliminate the hazards most likely to cause it. In construction, the top two causes of brain injury are falls and being struck by an object.

Fall protection:

- Handrails

- Warning Line Systems

- Scaffolds

- Covering holes

- Securing of ladders

Falling object prevention:

- Toe boards

- Netting

- Covered walkways/canopies at entrances

Training is also critical in the prevention and detection of TBIs. Workers often try to “walk it off” after being struck in the head, not realizing the potential danger. If you suffer from a head injury, report it to your supervisor immediately and seek medical attention.

The post Construction Workers at Highest Risk of Traumatic Brain Injury on the job appeared first on SMART Safety Group - Pacific Coast Operations.

Slips Trips & Falls 4 Jun 2015, 4:33 am

The post Slips Trips & Falls appeared first on SMART Safety Group - Pacific Coast Operations.

Vince Hundley’s Article Featured in Modern Contractor Magazine 18 Jun 2014, 5:54 am

The post Vince Hundley’s Article Featured in Modern Contractor Magazine appeared first on SMART Safety Group - Pacific Coast Operations.

HEAT ILLNESS STANDARD PROPOSED CHANGES 11 Jun 2014, 1:11 am

The Division of Occupational Safety and Health has just proposed major revisions to California’s heat illness prevention standard. The action is not formal rulemaking, but sending its proposal to the Standards Board is a big first step in revising the almost 10-year-old regulation. California has lead the nation in heat illness standards.

The Division of Occupational Safety and Health has just proposed major revisions to California’s heat illness prevention standard. The action is not formal rulemaking, but sending its proposal to the Standards Board is a big first step in revising the almost 10-year-old regulation. California has lead the nation in heat illness standards.

Employers with heat exposures may be well advised to begin adoption in advance.

Among the proposed revisions:

- Requiring employers to provide drinking water as close as practicable but no more than 400 feet from employees, with some wiggle room.

- Shade to be provided when temperatures hit 80 degrees (currently 85F) and no farther than 700 feet from workers.

- Employees who need to take a “cool-down rest” cannot be ordered back to work until symptoms of heat illness have abated. Employers also would have to monitor the worker during the rest period and provide emergency services if the symptoms worsen.

- High-heat procedures would kick in at 85 degrees, instead of the current 95F. The draft also adds specific instructions for observing employees for heat illness signs during high-heat.

- Expanding the training topics that must be provided to employees.

- Adding specific instructions on what must be contained in employers’ written heat illness prevention procedures.

- Requiring supervisors to take “immediate action” if employees show signs of heat illness. Such employees would have to be offered emergency medical services before they could be sent home.

Once the Standards Board reviews the draft, it might return it to DOSH for changes or for questions. No timetable has been set for formal adoption but this appears to be on a fast track.

The post HEAT ILLNESS STANDARD PROPOSED CHANGES appeared first on SMART Safety Group - Pacific Coast Operations.

Cal/OSHA Construction Crackdown Happening Now 28 May 2014, 1:58 am

May 27, 2014 – Cal/OSHA is deploying teams of investigators to construction sites throughout the state “to determine whether adequate measures have been taken to identify safety hazards and prevent injury,” it says. There will be focus on specific issues and employers should expect aggressive enforcement.

May 27, 2014 – Cal/OSHA is deploying teams of investigators to construction sites throughout the state “to determine whether adequate measures have been taken to identify safety hazards and prevent injury,” it says. There will be focus on specific issues and employers should expect aggressive enforcement.

Cal/OSHA is reacting to a series of recent fatal falls at construction sites around California. Cal/OSHA is fanning out to inspect worksites and puts employers on notice to pay attention to fall protection.

Investigators will be specifically checking safety railings, personal fall protection devices and equipment, and tie-offs. Cal/OSHA also will be looking for trench hazards, equipment safety and proximity to power lines. Cal/OSHA reminds employers that if it finds a lack of fall protection or other serious hazards, it can issue a stop-work order at the site, which will be in force until the hazard is abated. Employers deemed to be in violation safety standards also will be cited and ordered to correct the violations.

Three workers have died in the past two weeks and another survived with injuries. They include a May 18 fatality in Riverside when a worker tied off to a train bridge being dismantled rode down when the section toppled; a May 20 incident in San Mateo where a worker fell nine feet from a wall; and a May 21 death in San Jose where a worker unloading sheetrock from the third story of a building under construction fell over a railing from a sheetrock stack.

Copyright 2014 Providence Publications, LLC. All Rights Reserved. The Workers’ Comp Executive may be forwarded, copied or distributed subject to the following conditions: (1) The full report including text, graphics and links must be copied without modification and all pages must be included; (2) All copies must contain Providence Publications copyright notice; (3) This document may not be distributed for profit.”

The post Cal/OSHA Construction Crackdown Happening Now appeared first on SMART Safety Group - Pacific Coast Operations.

3 Most Effective Tools to Battle a Workers’ Comp Rate Increase 10 Sep 2013, 9:06 pm

In many hazardous industries, like construction, Workers’ Comp (WC) insurance is typically the third highest cost on the Profit & Loss statement. Even though WC rate increases are beyond your control, you can battle a rate increase by doing the following:

In many hazardous industries, like construction, Workers’ Comp (WC) insurance is typically the third highest cost on the Profit & Loss statement. Even though WC rate increases are beyond your control, you can battle a rate increase by doing the following:

1. Purchasing insurance from one of the most competitive carriers in your class code; and

2. Receiving the maximum scheduled credits from your carrier.

These two cost-cutting measures can be easily accomplished by doing the following 3 things:

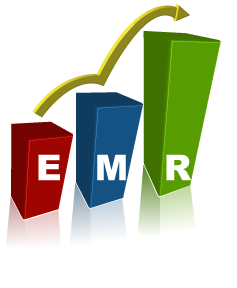

1. Lower your EMR

Experience Modification Rate (EMR), is the number that insurance carriers use to calculate your company’s risk. The higher your risk the higher your EMR, and correspondingly, the more you pay for your Workers’ Compensation (WC) Insurance. Having a low EMR equals profit!

Experience Modification Rate (EMR), is the number that insurance carriers use to calculate your company’s risk. The higher your risk the higher your EMR, and correspondingly, the more you pay for your Workers’ Compensation (WC) Insurance. Having a low EMR equals profit!

The good news is that you CAN completely control and even lower your company’s EMR by:

- Implementing an effective safety program;

- Creating a 12-month strategic training calendar;

- Auditing on a regular basis;

- Managing claims proactively; and

- Compiling monthly reports on all your safety activities.

By improving the effectiveness of your company’s safety practices and programs you will lower your EMR and make your company more marketable to insurance carriers.

Read: How EMR Can Improve Business Performance >>

2. Avoid Hiring Your Next Accident

If you are suffering from a high frequency or high cost of claims then the following suggestions will help your company.

If you are suffering from a high frequency or high cost of claims then the following suggestions will help your company.

- Conduct a Pre-Placement Physical at an Occupational Health Clinic. The cost of a pre-placement physical is a minor expense compared to the cost of a claim! The physical should include an alcohol and a 5-panel drug test.

- Implement a thorough New Hire Orientation ensures that your employee understands your company’s rules and regulations. You also need to get their signature of acknowledgement for your OSHA defense file.

- Develop a clear Claims Management Procedure that identifies who gets the first call when an accident occurs; who conducts the accident investigation; and who collects Supervisor Incident Reports, Employee Incident Reports, Witness Statements, and DWC-1 Claim forms

- Keep incidents First-Aid, instead of OSHA recordable, if at all possible. A trip to the Emergency Room can kill your bottom line, not to mention, negatively impact your insurance costs for years to come.

- Fight fraud aggressively by staying on top of each claim. Sometimes injured workers need to be reassured that they will be taken care of financially if their claim goes loss time. Know what signs to look for so you can sniff out fraud right away.

Read: Claims Management 101 >>

3. Create a Safety Culture

According to the Occupational Safety and Health Administration (OSHA), developing a strong safety culture has the single greatest impact on accident reduction.

According to the Occupational Safety and Health Administration (OSHA), developing a strong safety culture has the single greatest impact on accident reduction.

For this reason all companies should focus on creating a safety culture. In a strong safety culture, employees are empowered to identify and correct safety issues at all levels.

A “Say It When You See It” philosophy is key to creating a safety culture. For example, an apprentice feels comfortable walking up to a foreman and reminding them to wear their safety glasses. This behavior is not only encouraged, it’s rewarded in a strong safety culture.

How can a company instill a safety culture? They can adopt the four “E’s” of a SMART Safety Culture, which are:

- Establish safety as a core value

- Empower everyone

- Elevate safety advocates and eliminate opposition

- Exhibit a commitment to safety in all actions.

Learn practical steps you can take in order to establish a SMART safety culture at your company.

Read: The Four E’s of a SMART Safety Culture >>

In Conclusion

Don’t let Workers’ Comp rate increases negatively impact your bottom line and competitiveness. Take steps today to lower your EMR, avoid hiring your next accident and take steps to create a safety culture.

Don’t let Workers’ Comp rate increases negatively impact your bottom line and competitiveness. Take steps today to lower your EMR, avoid hiring your next accident and take steps to create a safety culture.

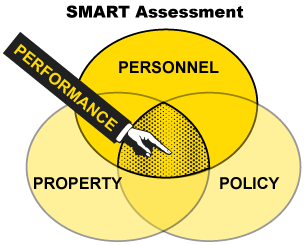

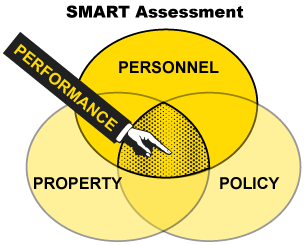

SMART Assessment

If you need help, contact us for a SMART Assessment. The SMART Assessment is designed to provide critical 3rd party feedback on your safety program. Our recommendations are designed to help you turn your safety program into a Profit Center instead of a Liability. Contact Us if you are interested.

The post 3 Most Effective Tools to Battle a Workers’ Comp Rate Increase appeared first on SMART Safety Group - Pacific Coast Operations.

3 Reasons to Outsource Your Safety Program 9 Sep 2013, 8:42 pm

For years, companies have elected to outsource business functions that are otherwise too expensive, too complicated, or too time-consuming. Just think of the most common business processes that companies outsource, like, manufacturing, information technology, and call centers. It is no wonder, then, that companies choose to outsource a complex, time-consuming business process like Safety Management.

For years, companies have elected to outsource business functions that are otherwise too expensive, too complicated, or too time-consuming. Just think of the most common business processes that companies outsource, like, manufacturing, information technology, and call centers. It is no wonder, then, that companies choose to outsource a complex, time-consuming business process like Safety Management.

Benefits:

- Gain an independent third party partner

- Implement a proven Safety system

- Free up management time

Independent Third Party

Why is an independent third party crucial? An independent third-party provides objective advice, transparency and expertise that are difficult to match internally. Since SMART Safety Group focuses on only one thing – safety, we have our pulse on industry trends and regulations. As a result, companies are able to cut their costs while gaining invaluable expertise.

Why is an independent third party crucial? An independent third-party provides objective advice, transparency and expertise that are difficult to match internally. Since SMART Safety Group focuses on only one thing – safety, we have our pulse on industry trends and regulations. As a result, companies are able to cut their costs while gaining invaluable expertise.

Too often, enforcement of safety policies or procedures can be uneven or unfair with an internal Safety Director – being either too soft on a work buddy, or too hard, coming across as a bully. As an independent third-party, SMART Safety Group will never get ensnared in office politics or show favoritism. Our feedback is always fair and unbiased.

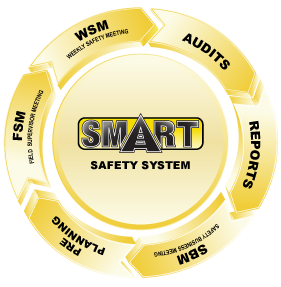

Proven Safety System

Second, SMART Safety Group has invested thousands of hours developing a SMART Safety System that is efficient, scalable and measurable. The system is performed on a monthly basis like clockwork. The consistent repetition of our Safety System creates a proactive safety culture, overtime, leading to less incidents and production loss. This translates into lower operating costs, making your company more competitive.

Second, SMART Safety Group has invested thousands of hours developing a SMART Safety System that is efficient, scalable and measurable. The system is performed on a monthly basis like clockwork. The consistent repetition of our Safety System creates a proactive safety culture, overtime, leading to less incidents and production loss. This translates into lower operating costs, making your company more competitive.

Aggressive Claims Management

In addition to auditing, training and safety business meetings, SMART Safety Group handles Claims Management. We have an aggressive claims management program, fighting fraud and keeping insurance rates low, allowing organizations to pass on these cost savings to their customers. SMART Safety Group’s team is available 24/7 by phone and typically on-site within an hour of an incident occurring, to perform accident investigation, triage and damage control.

“We hired SMART Safety Group back in 2006 for a 6-month trial run. We were having too many issues with our in-house safety program. A year’s worth of fees were saved in the first three weeks when one of our employees was injured. They handled the accident investigation, OSHA representation and claim, mitigating the penalties and costs down to almost nothing. They have been a part of our company ever since.”

– Brian T. Johnson, CFO/Controller,

Minshew Brothers Steel Construction, Inc.

Insurance Procurement

Workers’ Compensation (WC) Insurance is the 3rd highest cost on many company’s P&L. Lowering this cost, therefore, can make a huge impact on the bottom line. By linking Insurance, Safety and Claims Management, we are able to deliver bottom line results.

Buying WC Insurance is like buying life insurance. The insurance carrier checks boxes for items, such as, how many times a week you exercise, your tobacco use and your general health, to determine your rates. We help market your safety program to your WC Insurance carrier, enhancing your appeal, in order get you the lowest rate and earn you scheduled credits.

Competitive Advantage

Last, in today’s competitive environment, organizations with a strong safety program and safety culture establish a competitive advantage.

Last, in today’s competitive environment, organizations with a strong safety program and safety culture establish a competitive advantage.

Companies with a good reputation in their industry can attract the best workers, reduce operating costs, making them more competitive when looking for new or maintaining existing business. Also, by outsourcing safety, it frees up management time so they can focus on their core business. They can focus more on production and quality, knowing that they have a world-class safety program in place.

SMART Assessment

If you need help, contact us for a SMART Assessment. The SMART Assessment is designed to provide critical 3rd party feedback on your safety program. Our recommendations are designed to help you turn your safety program into a Profit Center instead of a Liability. Contact Us if you are interested.

The post 3 Reasons to Outsource Your Safety Program appeared first on SMART Safety Group - Pacific Coast Operations.

How EMR Can Improve Business Performance 9 Sep 2013, 8:28 pm

What is EMR?

EMR equals profit! EMR, or Experience Modification Rate, is the number that insurance carriers use to calculate your company’s risk. The higher your risk the higher your EMR, and correspondingly, the more you pay for your Workers’ Compensation (WC) Insurance.

EMR equals profit! EMR, or Experience Modification Rate, is the number that insurance carriers use to calculate your company’s risk. The higher your risk the higher your EMR, and correspondingly, the more you pay for your Workers’ Compensation (WC) Insurance.

In many hazardous industries, like construction, WC insurance is typically the third highest cost on the Profit & Loss statement. So having a high EMR can severely impact profitability and competitiveness.

The EMR is based on your company’s loss history for the previous three years, not including the immediate past year, as compared to industry average.

The baseline EMR is 1.0. The formula used to determine your EMR is complex, however, the important thing to know is that your EMR greatly affects your costs.

Compared to industry peers, if your company has fewer claims, your EMR will be lower. If you have more claims, your EMR will be higher, as will be your WC insurance premiums.

A company with an EMR of 0.8 will pay 33% less in Workers’ Compensation premiums than a company with an EMR of 1.2. Now that’s a competitive edge!

But you don’t have to accept a high EMR! There are ways to reduce both your EMR and WC Insurance premiums.

Who Determines EMR?

In California, the governing body for calculating the EMR is the Worker’s Compensation Insurance Rating Bureau.

The Bureau uses two major components to calculate your EMR:

1) loss severity, which measures loss amount and;

2) loss frequency, which measures how often claims take place. Having fewer and less expensive claims is the key to reducing both your EMR and insurance premiums.

Can I Lower My EMR?

In the real world, incidents are inevitable, however, they are often preventable. Incidents increase your EMR, leading to higher Workers’ Compensation insurance premiums.

The good news is that you CAN completely control and even lower your company’s EMR by:

- Implementing an effective safety program;

- Creating a 12-month strategic training calendar

- Eliminating hazards through regular audits;

- Managing claims proactively; and

- Compiling monthly reports on all your safety activities.

Companies can leverage an effective safety program to lower their EMR, reduce costs and gain a competitive advantage!

Summary

In today’s competitive marketplace, companies with a low EMR quickly establish a competitive advantage when looking for new or maintaining existing business. The EMR has a direct effect on your company’s overall operating costs, and profitability by determining how much you pay for Workers’ Compensation Insurance.

However, your company doesn’t need to be handicapped by a high EMR. You can decrease your EMR by creating a comprehensive safety program, a strategic training calendar for your employees, auditing regularly, managing claims proactively and by compiling the necessary reports.

By improving the effectiveness of your company’s safety practices and programs you will lower your EMR.

The post How EMR Can Improve Business Performance appeared first on SMART Safety Group - Pacific Coast Operations.

Claims Management 101: How To Avoid Hiring Your Next Accident 9 Sep 2013, 8:16 pm

Picture hiring a new employee and on the first day of work they show up drunk and become belligerent with their supervisor.

Is this realistic? Yes it actually happens quite a bit, but it can be avoided by conducting a pre-placement physical at an Occupational Health Clinic. The cost of a pre-placement physical is a minor expense compared to the cost of a claim!

Drug and Alcohol Test

On an employee’s first day of work, you should send them to the clinic for an alcohol and a 5-panel drug test (marijuana, cocaine, opiates amphetamines and methamphetamines).

On an employee’s first day of work, you should send them to the clinic for an alcohol and a 5-panel drug test (marijuana, cocaine, opiates amphetamines and methamphetamines).

You should also instruct the clinic to require the employee to perform the same physical activities they will encounter on the job, including bending, stooping, pulling, climbing and lifting a specific amount of weight. As the employee is performing the tests, the clinician will observe them for pain, unusual movements and visible scars.

Common questions a clinician should ask your new hire are:

- Do you have any aches and pains we should know about?

- Do you have any drug prescriptions?

- Have you been hurt at work before?

Once these items are thoroughly documented, your risk, as an employer, is greatly reduced!

New Hire Orientation

After your New Hire returns from their screening at the clinic, you need to run them through your New Hire Orientation Program. You should perform orientations in a classroom setting, instead of a  jobsite, for example, to ensure that you have your employee’s undivided attention. A thorough New Hire Orientation ensures that your employee understands your company’s rules and regulations. And you need to get their signature of acknowledgement for your OSHA defense file.

jobsite, for example, to ensure that you have your employee’s undivided attention. A thorough New Hire Orientation ensures that your employee understands your company’s rules and regulations. And you need to get their signature of acknowledgement for your OSHA defense file.

Claims Management Procedure

Even if you hire the best employees, some times stuff happens. How your company responds to an accident is extremely important. But you can’t wait till an accident occurs to react. You need a clear policy in place that identifies:

- Who gets the first call when an accident occurs;

- Who conducts the accident investigation even for the most minor of accidents; and

- Who collects Supervisor Incident Reports, Employee Incident Reports, Witness Statements, and DWC-1 Claim forms

First-Aid Vs. Recordable

A trip to the Emergency Room can kill your bottom line, not to mention, negatively impact your insurance costs for years to come. Anytime an employee gets hurt you should provide the necessary  medical treatment while trying to keep the incident First-Aid, instead of OSHA recordable, if at all possible. Once an accident is recordable, your insurance carrier is notified and your Experience Modification Rate (EMR) is negatively impacted.

medical treatment while trying to keep the incident First-Aid, instead of OSHA recordable, if at all possible. Once an accident is recordable, your insurance carrier is notified and your Experience Modification Rate (EMR) is negatively impacted.

What is Considered First-Aid?

- Tetanus immunizations

- Cleaning wounds

- Bandages, Steri-Strips and non-rigid back belts

- Hot or cold therapy

- Temporary immobilization devices while transporting an accident victim

- Drilling of a fingernail or toenail to relieve pressure, or draining fluid from a blister

- Using eye patches

- Removing foreign bodies from the eye using only irrigation or a cotton swab

- Removing splinters or foreign material from areas other than the eye by irrigation, tweezers, cotton swabs or other simple means

- Using finger guards

- Using massages

- Drinking fluids for relief of heat stress

Aggressive Claims Management

Once an accident happens, you have to aggressively manage it to minimize the long-term impact on your company. Here’s a list of things that you can do:

- Get to know the claims examiner

- Get to know the Primary Treating Physician

- Always know what the injured worker is doing.

- Keep a record of medical treatment

- Know when the next doctor’s visit is scheduled

- Immediately follow up with the injured worker following the visit with the physician.

- Offer modified work at all costs!

Fighting Fraud

Sometimes injured workers need to be reassured that they will be taken care of financially if their claim goes loss time. Even with reassurance, some employees may decide to file a fraudulent claim. By staying on top of each claim, you should be able to sniff out fraud right away. In order to fight fraud, here’s what you should look out for:

Sometimes injured workers need to be reassured that they will be taken care of financially if their claim goes loss time. Even with reassurance, some employees may decide to file a fraudulent claim. By staying on top of each claim, you should be able to sniff out fraud right away. In order to fight fraud, here’s what you should look out for:

- Someone with an unstable work history

- Someone who is consistently uncooperative

- Someone who was recently terminated, demoted or in line for early retirement

- Someone who calls soon after being injured and presses for a quick settlement of the case

- Someone who changes their address to a post office box or receives mail via a friend or relative

- Someone not injured in the presence of witnesses

- A history of reporting subjective injuries

- Not promptly reporting the accident to the employer

- Accidents occurring late Friday afternoon or shortly after the employee reports back to work on Monday morning.

Where To Start?

If you need help with your Claims Management program, contact us for FREE, we would love to help. You may also consider outsourcing your program to SMART Safety Group. The three main benefits are, you will:

If you need help with your Claims Management program, contact us for FREE, we would love to help. You may also consider outsourcing your program to SMART Safety Group. The three main benefits are, you will:

- Gain an independent third party partner

- Implement a proven Claims Management Program

- Free up management time

The post Claims Management 101: How To Avoid Hiring Your Next Accident appeared first on SMART Safety Group - Pacific Coast Operations.